It suitable PVC foam board machine and WPC board machine, We use SJSZ80/156 +SJSZ65 conical double screw extruder high output.

It suitable PVC foam board machine and WPC board machine, We use SJSZ80/156 +SJSZ65 conical double screw extruder high output.

Leading the company’s elite team and all employees to develop and create a pragmatic. Comprehensive, unique and novel corporate culture of Qingdao Jiashang Automation Equipment Co., Ltd. which has been used for reference by many domestic enterprises.

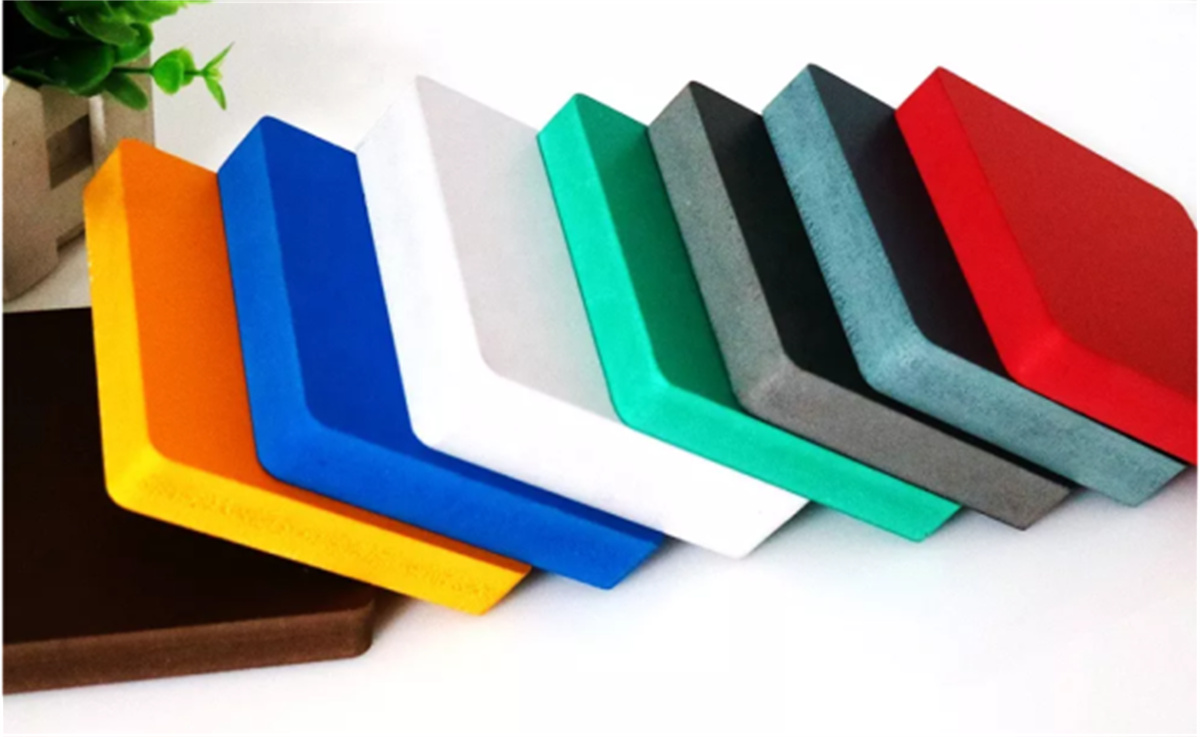

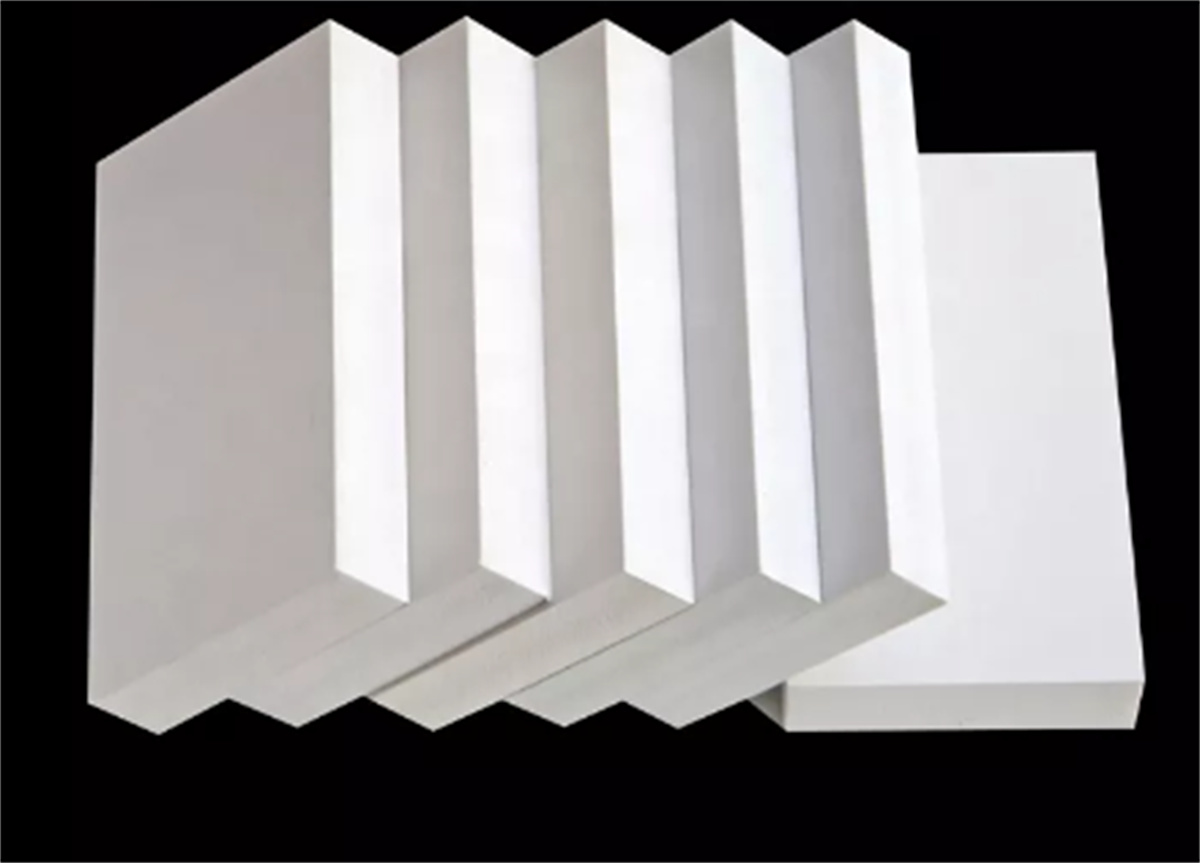

Our company is a collection of research and development, production, sales in one of the PVC foam board production line machine processing manufacturers, the production line can produce by adjusting the formula process: black and white PVC free foam board, PVC crust board, PVC cabinet board, bath cabinet board, and a variety of irregular plate extruders, extrusion plate products are widely used in: advertising carving industry, decorative materials, bath cabinet production, interior decoration board, building exterior wall panel, interior decoration board Office, residential, public place building compartment, commercial decorative frame, Clean room boards, screen printing, computer lettering, advertising signs, exhibition boards, sign boards and other industries and chemical anti-corrosion engineering, thermoforming parts, cold storage boards, special cold preservation engineering, environmental protection plate molds, sports equipment, breeding materials, coastal moisture-proof facilities, water-resistant materials, art materials and various lightweight partitions instead of glass ceilings.

General description:

1. Product size: width 1250mm/thickness: 3-30mm (Based on customer's requirement)

2. Main Material: WPC Compounding, PVC, processing additives and filling agent

3. Extruder: SJSZ80/156 conical double screw extruder+SJSZ65

4. Output: around 7-10ton/day

5. Cooling water temperature: <15℃ Air pressure: > 0.6Mpa

6. Power supply: 3Phase /380V/50HZ (Based on customer's requirement)

Machine specification

|

PVC Foam Board Extrusion Line For Fish Tank Base Cabinet |

||||

|

Model |

Product Width |

Product Thickness |

Capacity |

Main Motor Power |

|

SJSZ80/156+65/132 |

1220mm |

3-30mm |

500kg/h |

75+37kw |

Co-extrusion Color PVC Foam Decking Board Production Line Manufacturers.

The conical twin-screw extruder has stable performance, which can make the melt plasticize well at a lower temperature. The cast aluminum heater is installed on the cylinder, which has high thermal efficiency, fast and uniform temperature rise, and is equipped with cooling fan.

Post time: Mar-29-2023