-

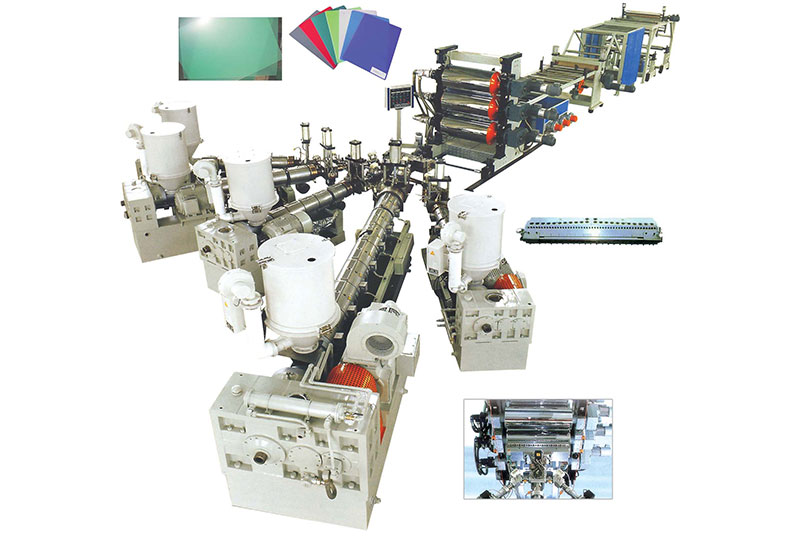

Co-extruded PVC Foam Board Extrusion Line

Co-extruded PVC Foam Board Extrusion Line,PVC Co-Extrusion Foam Board Extrusion Production Line :Our PVC Foam Core Board Production Line Machine includes the special Twin-screw extruder, mould and other auxiliary machines. Our factory use twin-screw extruder with compact structure, superior performance. Besides the screw and barrel and die are designed by our company and made in world famous manufacturers. And use the high-performance alloy steel for professional processing. So the machine has the advantages of uniform plasticizing, stable extrusion, high output, and long life. We can supply you the best material formulation and all of technology. We have several thousand kinds of formula through 15 years’ researches. PVC or WPC foam board production line with big output, stable extrusion, high foaming, good and wear-resisting surface and so on.

-

SJSZ80 PVC crust foamed sheet production line

Application:

This equipment is mainly used for producing wood plastic foam board sheets.The line produced plates are applied in interior decoration,furniture,cabinets,sanitary wares,advertising boards,art materials,templates of construction and sound insulation,etc.The production is so widely used with enormous prospects.Plastic PVC Foam Board Wall Panel Skinning Machine Extruder Production Line PVC Foam Board Machine

-

WPC Furniture PVC Foam Kitchen Cabinet Board Making Machine

WPC PVC Crust/Skinning/Celuka Foam Board Extrusion Making Machine

Raw materials used in manufacturing:

PVC material + plant fiber(wood power, rice chaff etc)+necessary chemical ingredient

Process flow:

1. Wood > Wood powder > (wood flour dryer)

2. PVC material + wood flour + necessary ingredient > WPC mixing equipments–> WPC board Extrusion Line–>WPC board profile-hot transfer printing -

PVC foam board Production line

PVC foam board Production line

- High quality components come from international standards

- High efficiency and energy saving design and easy operation

- Professional research and development of PVC foam board/sheet machinery, Export to nearly 20 countries

- Plastic PVC WPC Cabinet foam board extrusion line, PVC/WPC Sheet Making Machine Production Line,

- Celuka Foam PVC WPC Crust Foam Board Production Line Machine

-

PVC Crust Foam Board Machine

Practical Application:

Traffic and Transportation: Roof, sandwich layer, inside upholstering plate for carriage of ship, plane, automobile, train, etc.

Construction Upholstering: Wall panel outside and inside building, partition board, plate for non-dust room, plate of hung ceiling, etc.

Advertising: Printing, nameplate, showing plate, etc.

Industry Use: Kinds of plates.

Furniture: Kitchen, washing room, indoor decorative material, etc.

Others: Template, exercise equipment, material for feeding use, water resistant facility by sea, etc.High Quality PVC Crust Plate / WPC Wood Plastic Foam Board Sheet Extrusion Production Making Machine for Furniture Decoration Kitchen.Professional PVC WPC Free Foam Board Sheet Extrusion Line Plastic Machinery

-

PVC WPC wood plastic composite celuka foam board Extrusion Machinery Series

Celuka Foam Board Sheet Extruder Extrusion Line Making Machine:

Plastic WPC PVC Foam Board Extrusion Machine/Machinery ,Plastic board extrusion line is used to produce plastic board with width from 600 to 1250mm, which are effective、safe

Capacity: Conical twin-screw extruder, suitable for process PVC powder with high capacity.Diameter: We have very successful production experience.Auxiliary machine closely meet customer specifications. Nice apperance, automatic control and stable running performance.

-

Multi-layers co-extrusion plastic sheet board extrusion line

PS Co-Extrusion Sheet Production Line/Plastic Sheet Production Line Manufacturers,Multi Layer Plastic Sheet Extuder Sheet Extrusion Line

ABS HIPS ABS PMMA Multi-Layers Sheet Plate Board Extruder Machine Extrusion Line

1. pp sheet extrusion line is capable of continuously producing mono-layer or multi-layer PVC/PP/PE/ABS/PMMA/PC/PS/HIPS plate and sheet with the width less than 3000mm and thickness of 0.25-30mm .The products are widely used in the fields of refrigerater, air conditioner, auto, advertisement, and construction, environment protection, etc.

2. pp sheet extrusion line includes many equipments, such as :extruder, screen changer and mould, three-roller calendaring machine, bracket of cooling roller, landscape orientation cutting machine and the winder.

3. this machine can do Single Layer, Multi-Layers Composite Sheet Production Line

-

plastic PVC sheet board extrusion line

Plastic Sheet/Board Extrusion Machine ,plastic PVC sheet board extrusion line General:

Power supply: 380V/ 3P/ 50HZ or on request

Suitable material: PVC blend

Sheet width: 1400mm, sheet thickness: 0.2-1mm, cutting length can be set

Max. extrusion capacity: 350kg/h

Total installation power: 200kw -

PA11 Nylon single wall corrugated pipe machine for car

PVC spiral steel wire hose extrusion line The Single and Double Wall Corrugated Pipe Extrusion Machine for Electrical Use are widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc. Single and Double Wall Corrugated Pipe Extrusion Machine for Electrical Use developed by our company adopts gears to run modules and templates so as to realize water circulating cool... -

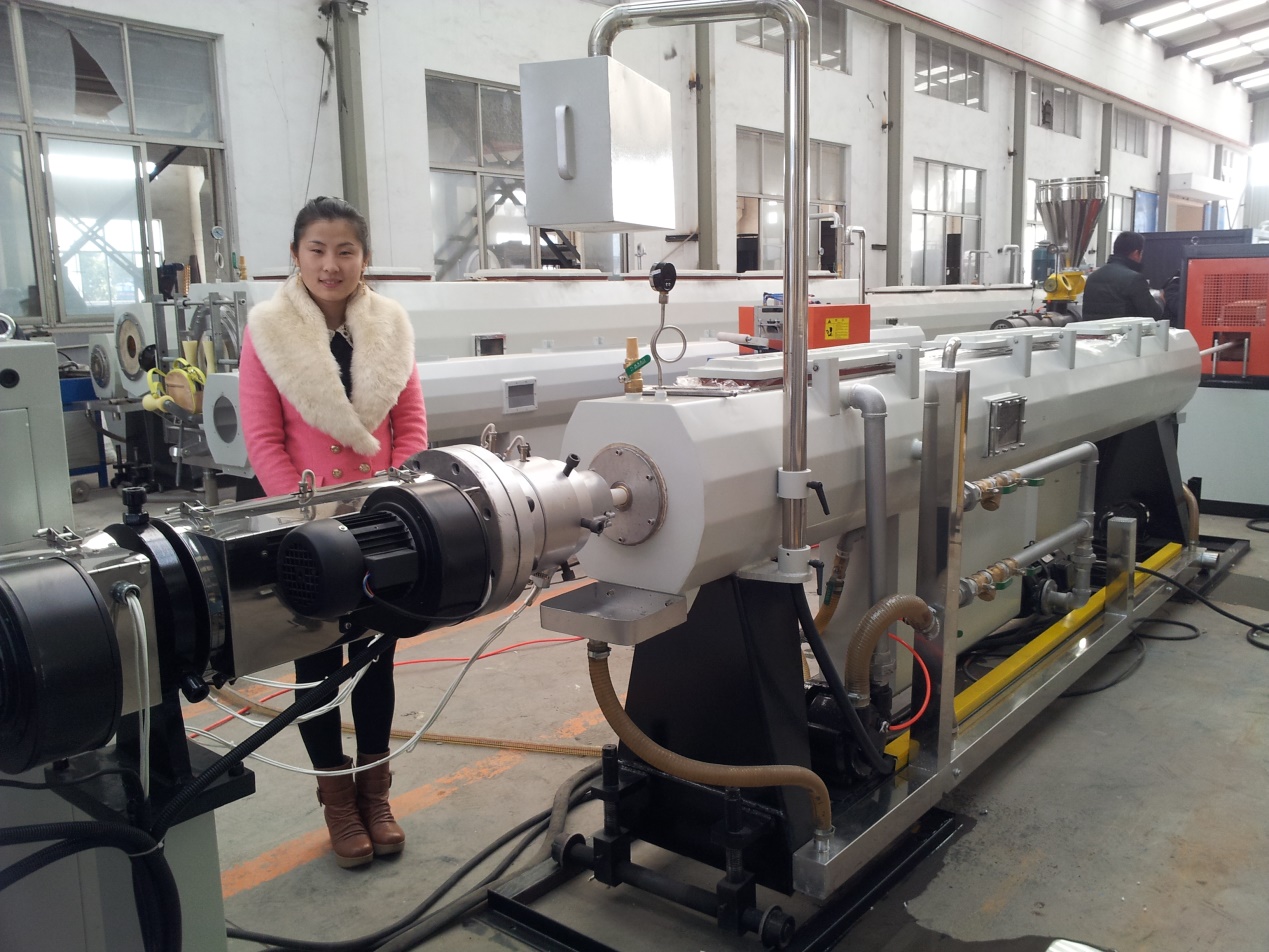

16―110mm PE pipe production line

PE/PPR Pipe Extruder Extrusion Machine Making Production Line

20-110 PE/HDPE PPR Pipe Extrusion Pipe Production Line

A. Necessary Machines for 16-110mm PE Pipe Extrusion Line

- 1 set of automatic vacuum loader

- 1set of hopper dryer

- 1 set of Single-Screw Extruder – SJ75/33

- 1 set of SJ25/25 co-extruder

- 1 complete set Moulds for16-110mm

- 1 set of Vacuum Calibration and Cooling water Tank

- 1 set of Cooling tank

- 1 set of two pedrails tractor

- 1 set of printer

- 1 set of free dusty Cutter

- 1 set of stacker (if you need PE pipe winder, then please advise us )

-

50-110mm PVC pipe production line

50-110mm PVC pipe production line

Water Supply Drain Tube Electrical Conduit Threading Twin Screw Extruder

1. Over current protective of motor

2. Over pressure protective of screw. -

PE Carbon Composite Spiral Pipe Extrusion Line

PE Carbon Composite Spiral Pipe Extrusion Line,The spiral corrugated pipe product has special spiral physical structure, the pipe material mechanical performance is good, the compressive strength, pipe buried under deformation, inner spiral uniform cable around the cooling efficiency and effectively protect the security of the cable.