WPC Furniture PVC Foam Kitchen Cabinet Board Making Machine

List of machines and advantages

|

NO. |

Name of machine |

Advantage of machine |

|

1 |

Automatic feed loader |

Fully automatic |

|

2 |

Conical Twin Screw extruder |

Inverted SIEMENS motor, famous brand gearbox and full set of SIEMENS electric control system,30% ENERGY SAVING, STABLE RUNNING, LONG SERVICE LIFE |

|

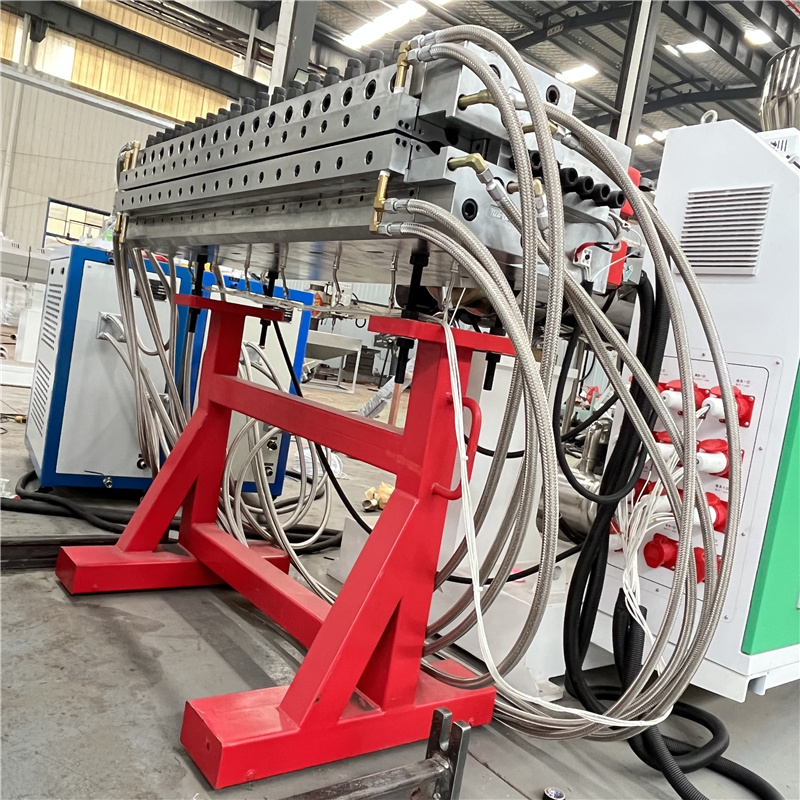

3 |

T-die |

Design by ourself with over 15 years manufacturing experience |

|

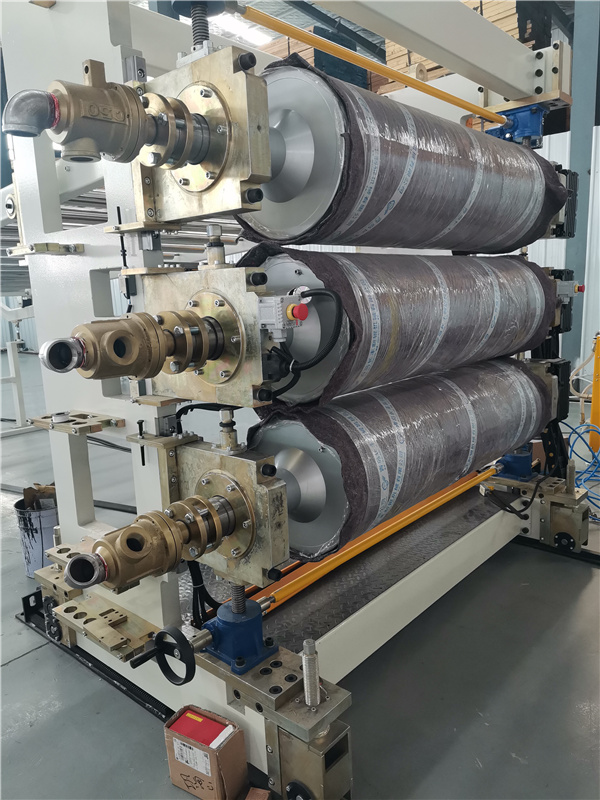

4 |

Calibrator |

100mm thickness mirror surface calibrator |

|

5 |

Cooling Bracket |

9 pcs stainless iron rollers |

|

6 |

Haul off machine |

8-12 pairs rubber surface rollers |

|

7 |

Transverse cutter |

|

|

8 |

Stacker/manipulator |

|

| Auxiliary machines(optional) | ||

|

1 |

Crusher |

For recycling unqualified board |

|

2 |

Grinder /Pulverizer |

For recycling unqualified board |

|

3 |

High-speed Heat/Cooling Mixer |

For mixing raw materials |

|

4 |

Chiller |

To supply cool water |

WPC Foam Plastic Furniture PVC Kitchen Cabinet Board Making Machine

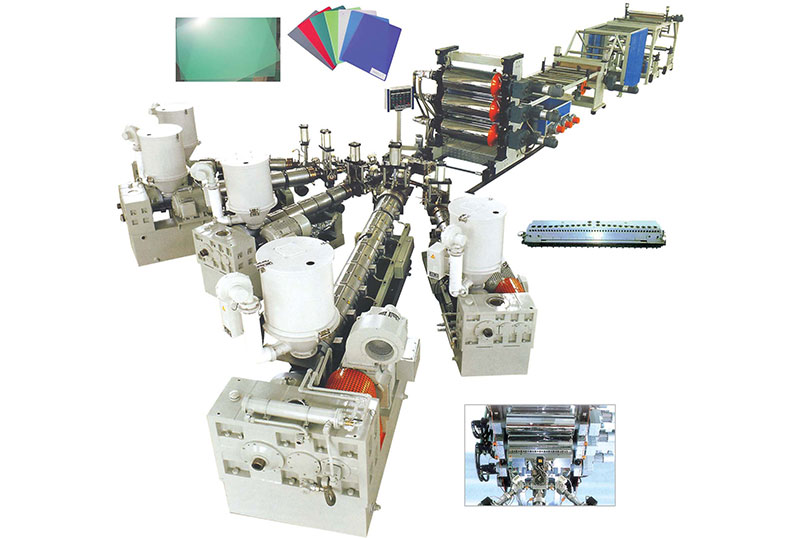

PVC/WPC board machine can continuously produce PVC WPC foam board.This production line is composed of extruder, mould, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.

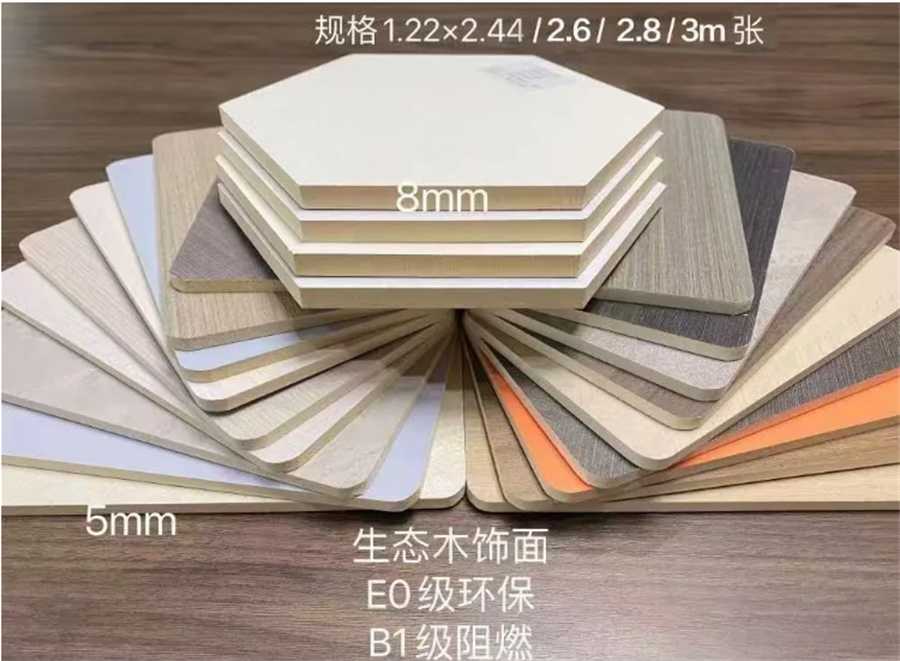

The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

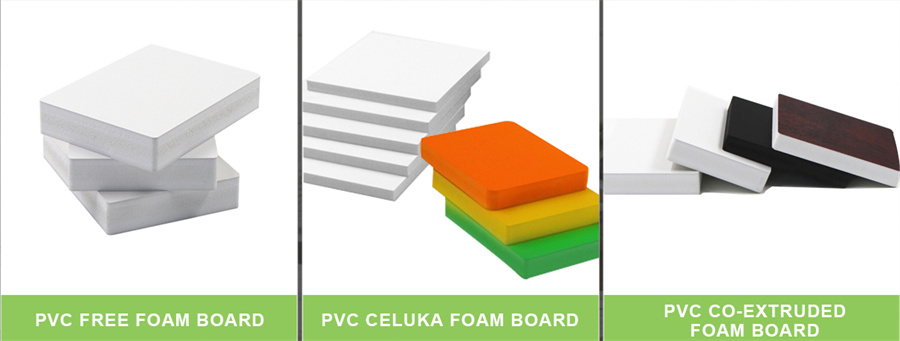

PVC foamed board belongs to the new environmental protection material, called no defect board in foreign countries, and the double post, no oil leakage, no water seepage, scratch resistant, also called blister board, base material of density board, surface by vacuum blister or adopt a seamless and PVC film pressure molding process, green non-polluting, renewable, is the ideal alternative ambry materials, and the people life more convenient, the most suitable. Door plate in normal size without edge, waterproof, moisture-proof, hardness and flexibility.