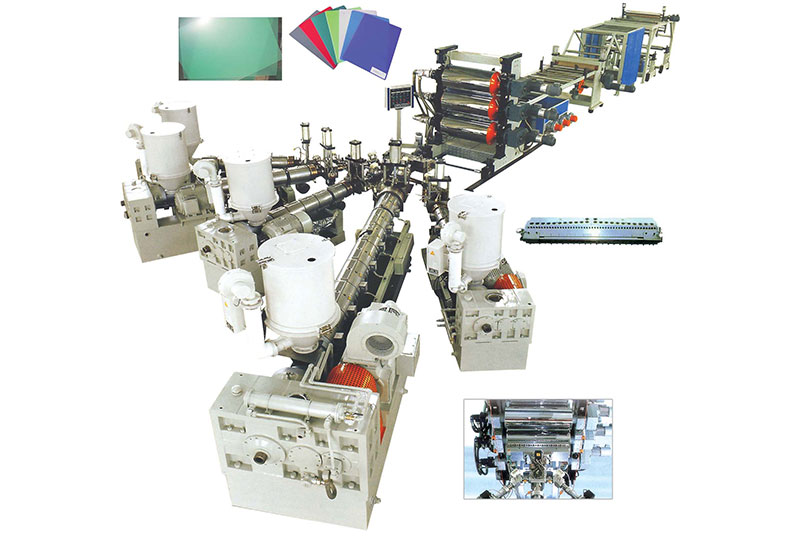

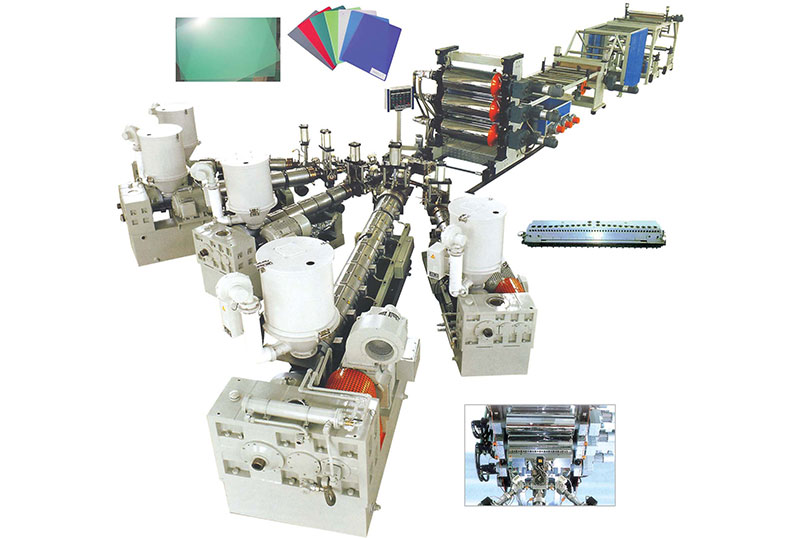

Co-extruded PVC Foam Board Extrusion Line

Machine specification

|

PVC Foam Board Extrusion Line For Fish Tank Base Cabinet |

||||

|

Model |

Product Width |

Product Thickness |

Capacity |

Main Motor Power |

|

SJSZ80/156+65/132 |

1220mm |

5-20mm |

500kg/h |

75+37kw |

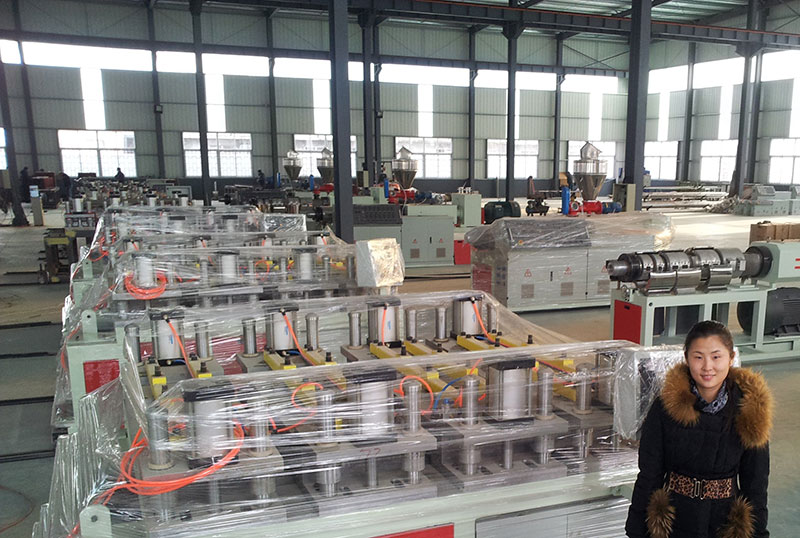

Co-extrusion Color PVC Foam Decking Board Production Line Manufacturers

The conical twin-screw extruder has stable performance, which can make the melt plasticize well at a lower temperature. The cast aluminum heater is installed on the cylinder, which has high thermal efficiency, fast and uniform temperature rise, and is equipped with cooling fan.

|

Machine List |

|||

|

No. |

Name |

Qty. |

Remark |

|

1 |

Screw loader for extruder |

1 |

|

|

2 |

SJZ 80/156 conical twin screw extruder |

1 |

|

|

3 |

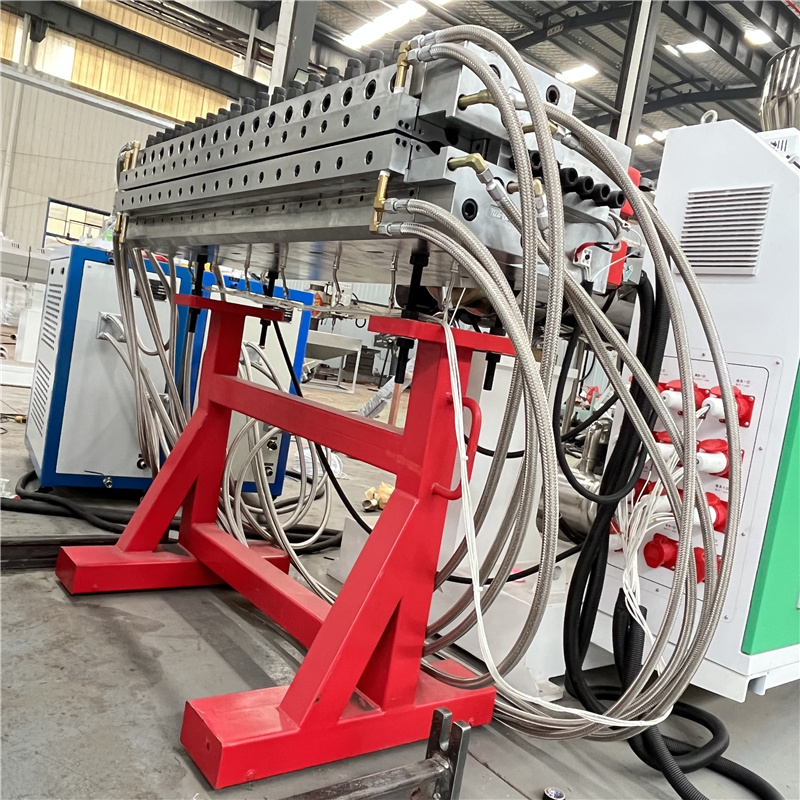

Extrusion mould unit |

1 |

1220*2440 |

|

4 |

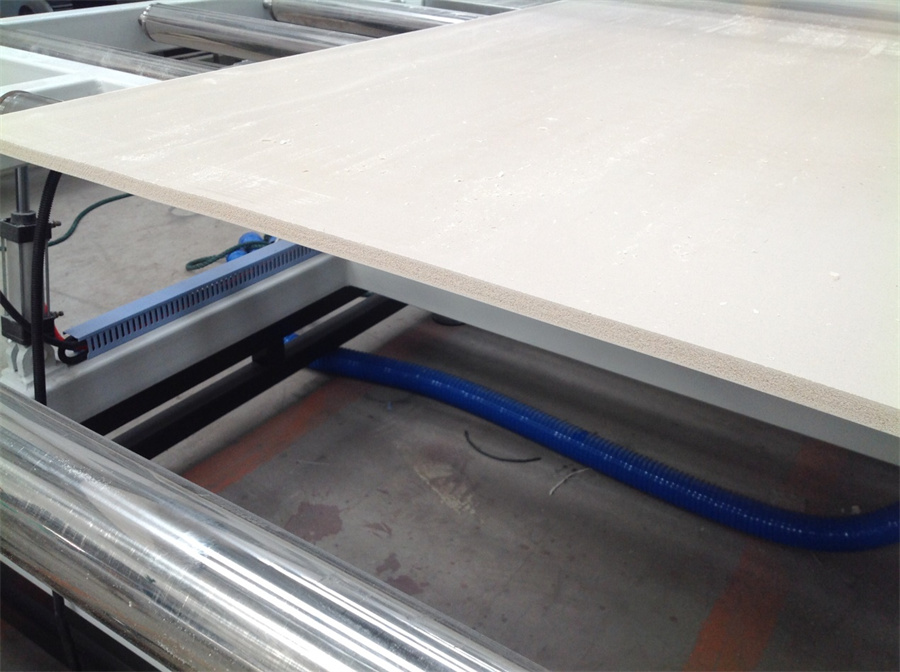

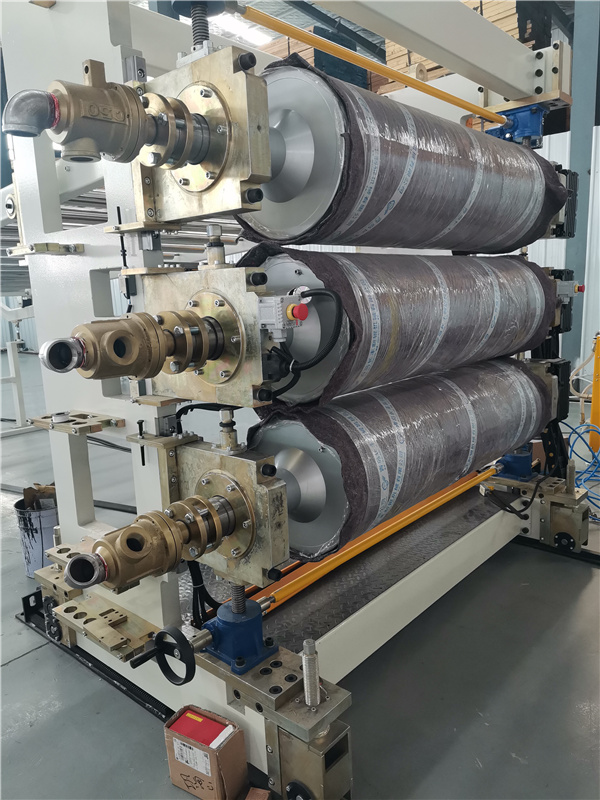

Vacuum calibration Table |

1 |

|

|

5 |

Cooling bracket |

1 |

|

|

6 |

Haul off unit |

1 |

|

|

7 |

Edge cutting device |

1 |

|

|

8 |

Tracking cutter |

1 |

|

|

9 |

Automatic shift machine |

1 |

|

|

10 |

Dust collection device |

1 |

|

|

11 |

Mould temperature controller |

1 |

|

|

Auxiliary Machine |

|||

|

12 |

SRL-Z Series Mixer unit |

1 |

Capacity : 450-550kg/h |

|

13 |

Screw loader for Mixer |

1 |

|

|

14 |

Crusher |

1 |

Power: 11kw,22kw,30kw |

|

15 |

Pulverizer |

1 |

Power: 45kw,55kw,75kw |

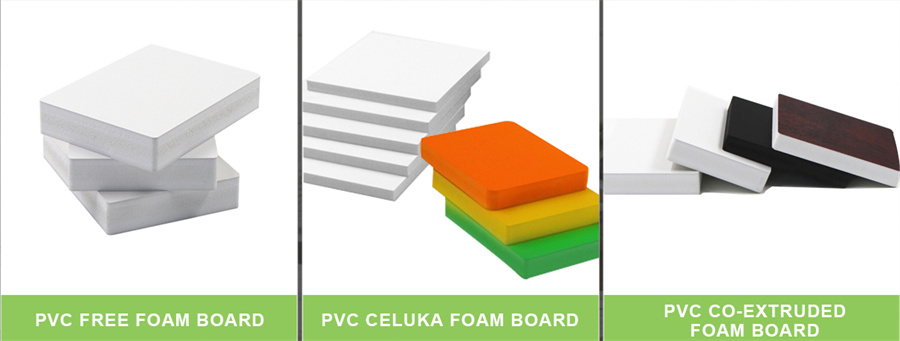

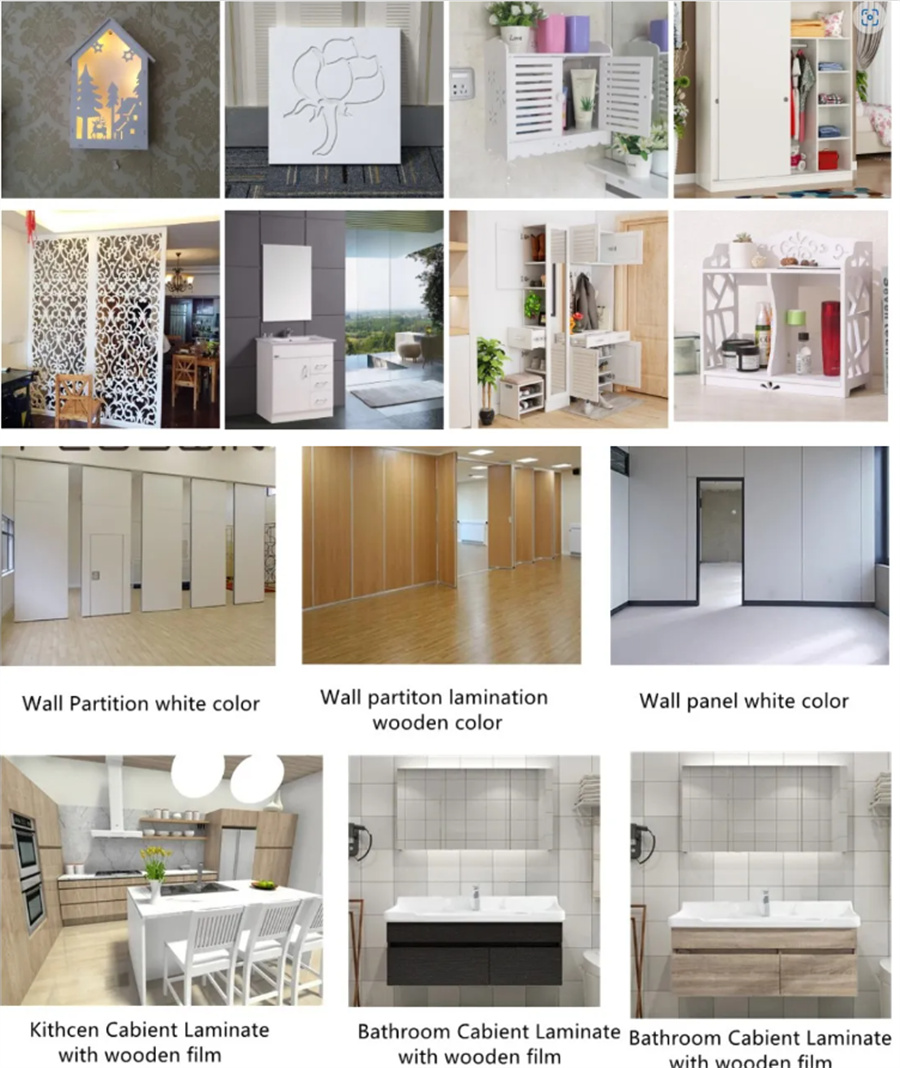

Application

Architecture decoration industry:

building template board, outdoors plate, indoors decoration plate, residential house, office, separation of public building, commercial decoration frame, plate used in dust-free room, celling plate.

Household decoration:

bathroom cabinet board, kitchen cabinet, furniture board, home decoration board, various household shelves.

Advertisement industry:

Screen printing, computer engraving, advertising board, exhibition plate, logo plate.

Transport industry:

ship, plane, bus, and train, floor covering, core layer, indoors decoration plate.

Industrial application:

rot proof project in chemical industry, thermal shaped part, plate for refrigeration warehous, special cool-keeping protection plate.

Other applications:

construction mold plate, sports apparatus, aquaculture material, seashore wet-proof facility, water-resistant material, arts material and all sorts of light separation plate.

FAQ

1. How many electric, water, air need for the machines?

JIASHANG: technical department supply the whole layout for workshop details.

2. Can I operate machine if don’t have experienced engineers?

JIASHANG: (1) short-time engineers to customer company (5-15days)

(2) Year-time working as requirements

3. Any quality checking before shipment?

JIASHANG: 100% confirm, run and test machines before shipment with quality certificate.

4. How long is the guarantee?

JIASHANG: 12 months since the first day customer operates (we supply some spare parts free)

5. How can u help us when face some technical problem?

JIASHANG: 24 hours by e-mail,wechat or whatsapp message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

6. Where can we get spare part?

JIASHANG: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, ABB,DELTA etc, or send parts by DHL, Fedex, TNT and other express.

We have professional technology team and sales team, a team of electromechanical commissioning engineers. Our factory can accurately provide a complete raw material formulation process, to help you produce different plastic products.