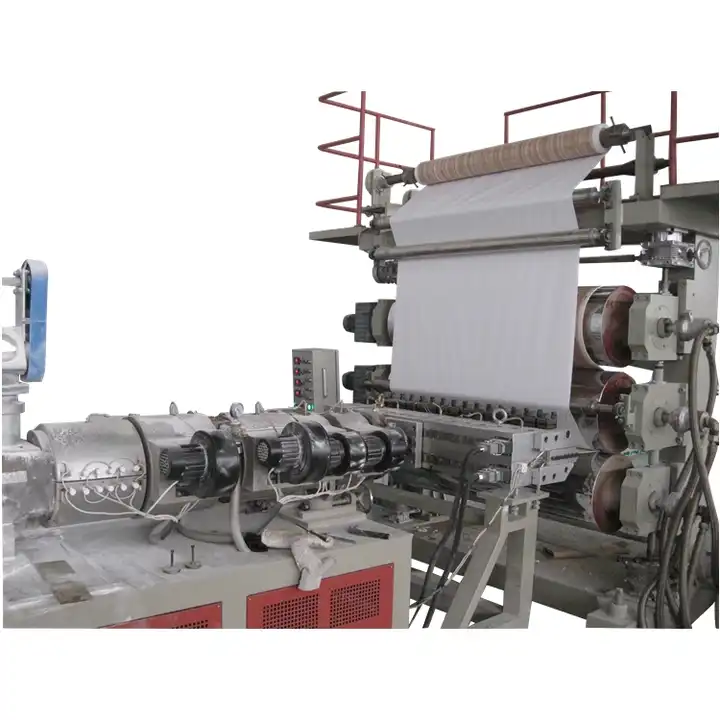

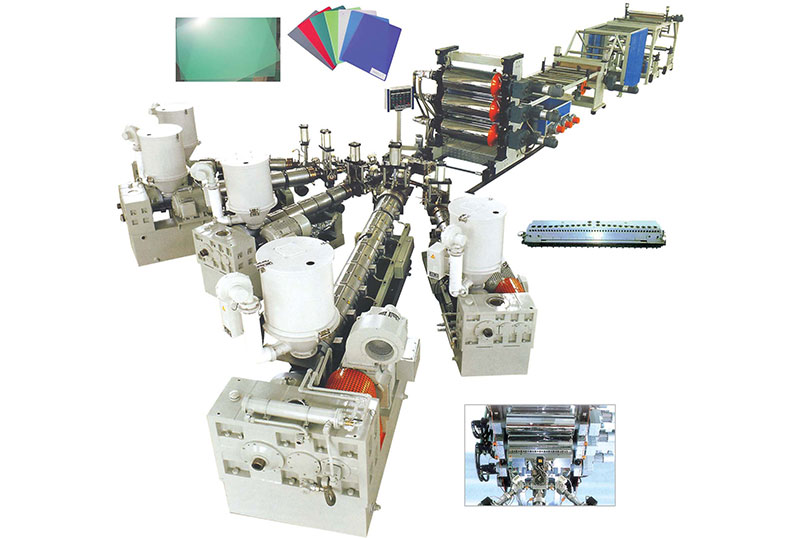

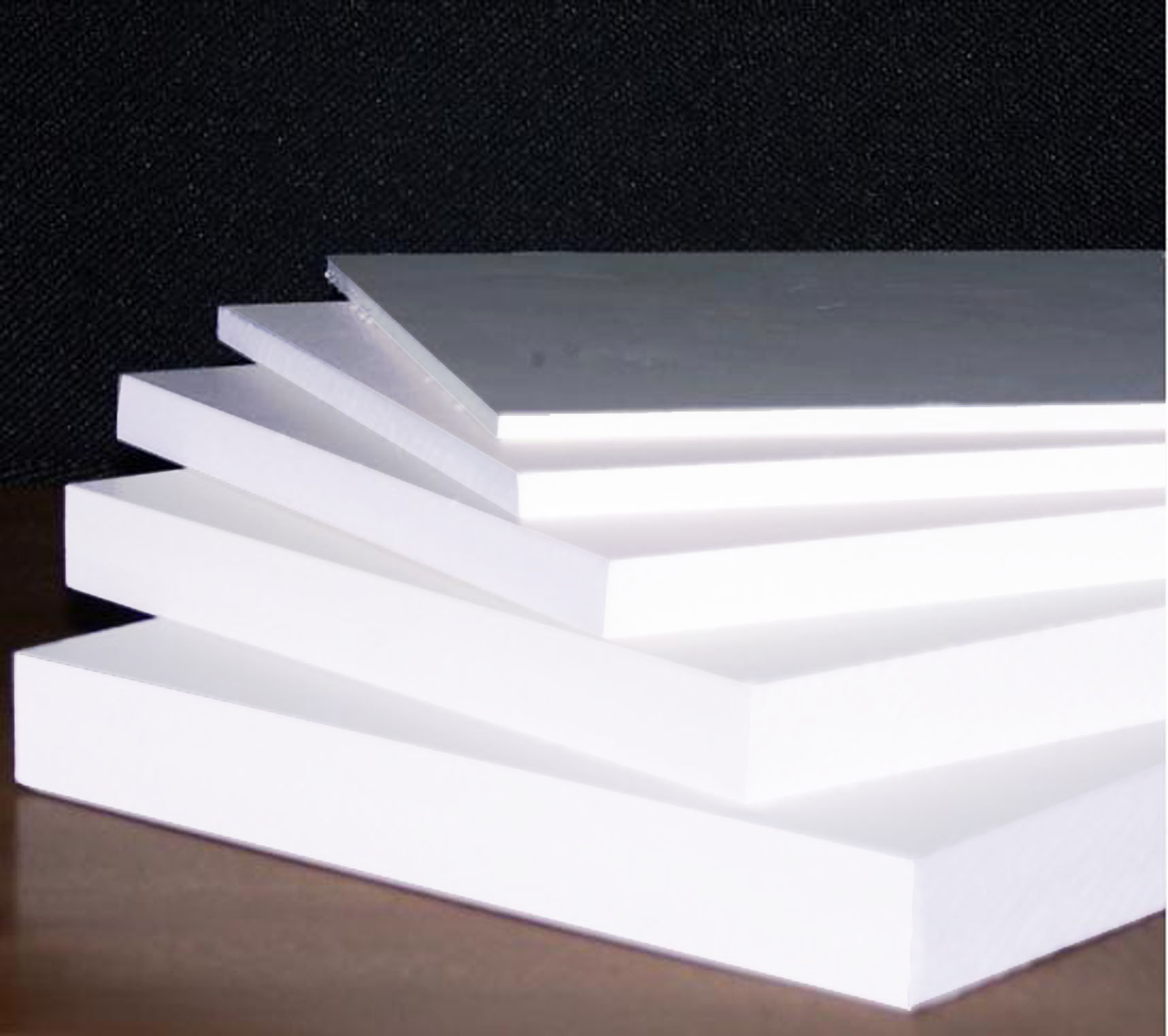

WPC PVC Crust Foam Board Extrusion Line

Detail Technical Parameters

(Picture only for reference)

General description

1、Product size: width 1250mm/thickness:2-30mm (Based on customer’s requirement)

2、Main Material: WPC Compounding , processing additives and filling agent

3、Extruder: SJSZ80/156 conical double screw extruder

4、Output: around 7ton/day

5、Cooling water temperature: <15℃ Air pressure: > 0.6Mpa

6、Power supply: 3Phase /380V/50HZ (Based on customer’s requirement)

B. Detail Technical Parameters of Each component

1. Screw Automatic loader

| Item | Description | Unit | remarks |

|

|||

| 1 | Rated Charge Capacity | Kg/h | 450 |

| 2 | Max charge capacity | Kg/h | 450 |

| 3 | Motor Power | KW | 1.5 |

| 4 | Hopper volume | Kg | 120 |

| 5 | Spring diameter | mm | 36 |

| 6 | Storage volume | kg | 150 |

2. SJSZ80/156 Conical Double Screw Extruder

| ﹡Screw、barrel design and manufacturing absorb European advanced technology

﹡Screw and barrel material:38CrMoAlA,Nitriding treated ﹡adopt original famous electric components with high steady running quality . Eg: RKC or Omron temperature controller、ABB speed regulator、low-voltage breaker adopts Schneider or Siemens ﹡Gearbox adopt high torque, low noise, hard gear tooth face gear box ﹡Self protective system: current of motor overload automatic stop protection screw displacement automatic stop protection Lubrication oil starvation automatic alarm device |

|||

| 1 | Screw Diameter | mm | ¢80/156 |

| 2 | Screw Length | mm | 1800 |

| 3 | Screw rotation speed | r/min | 0-37 |

| 4 | Material of Screw and Barrel | / | 38CrMoAlA Nitrogen Treatment |

| 5 | Depth of nitration case | mm | 0.4-0.7mm |

| 6 | Hardness of nitration | HV | 》950 |

| 7 | Roughness of the surface | Ra | 0.4un |

| 8 | Hardness of double alloys | HRC | 55-62 |

| 9 | Depth of double alloys | mm | 》2 |

| 10 | Heating Power | KW | 36 |

| 11 | Barrel Heating | / | Casting Aluminum Heater |

| 12 | Screw core temperature control | / | Automatic cycle temperature control |

| 13 | Heating zones | / | 4 |

| 14 | Cooling | / | blower cooling |

| 15 | Screw core temperature adjusting | / | By circle conduction oil |

| 16 | Screw quantity | 2pcs | |

| Machine frame | Welding of steel pipe and iron plate | ||

| Gear box | |||

| 1 | Applicable standard | / | JB/T9050.1-1999 |

| 2 | Material of gear and shaft | / | Adopt high strength alloy, carburizing and quenching, grinding |

| 3 | Gear precision and hardness | / | 6grade, HRC 54-62 |

| 4 | Oil sealing | All sealing adopt good products | |

| 5 | Screw Safeguard | / | Automatic screw displacement alarm |

| 6 | Brand | DUOLING (JIANGYIN) | |

| 7 | gear bearing | NSK | |

| 8 | gear bearing MATERIAL | 20CrMnTi Nitriding hard tooth surface | |

| Dosing feeding device | |||

| 1 | Feeding speed regulator | / | ABB frequency conversion |

| 2 | Can be adjusted separately or synchronized adjusting with extrusion. | ||

| 3 | Feeding motor 1.5kwMaterial stainless steel | ||

| Motor and electric system | |||

| 1 | Motor Power | KW | 75(AC motor) |

| 2 | Speed adjusting mode | / | Variable frequency conversion |

| 3 | Output Capacity | Kg/h | 400 |

| 4 | Temperature Controller | / | RKC, Japan |

| 5 | Frequency inverter | / | ABB |

| 6 | AC contactor | / | Siemens |

| 7 | Voltage | / | According to requirement |

| 8 | Motor brand | Siemens | |

| 9 | Extruder axis height | mm | 1000 |

| 10 | |||

3. Die head and calibrating Moulds (including mould temperature controller)

| Item | Description | |

| Regulating device with choke plug: 1 set of die lip. The upper die lip can be adjusted and the lower die lip can be replaced. Equipped with die holder with adjustable die lifting.The mold lip is equipped with a circulating heat transfer oil device, equipped with a mold temperature machine.

Effective width of die head: 1350mm Channel mode: clothes hanger channel is adopted Product width: 1220mm Thickness of foam board products: 3-25mm Heating section: Zone 7 The die is made of high-quality alloy steel and die steel forgings, and the surface of the inner runner is chrome plated and polished. Mold structure: the mold structure absorbs imported technology, and the interior of the mold cavity is plated with hard chromium and polished to a bright mirror. Thickness adjustment: adjustable bolts are set on the die lip, which can be adjusted when producing plates with different thickness Heating form: stainless steel electric heating rod is used for heating, with uniform discharge and good stability Mold trolley, bracket type, with traveling wheel. Material: square tube steel plate welding reinforced structure Adjustment method: screw adjustment Adjustment height: 100mm |

||

PVC foam board machine Spare parts :Accessories list:

| NO | Spare parts name | Quantity |

| 1 | Cast alumium heater for 1 zone | 1 pcs |

| 2 | Cooling air fan for barrel | 1 pcs |

| 3 | Spanner for mould | 1 pcs |

| 4 | contactors | 2 pcs |

| 5 | Thermocouples | 5 pcs |

| 6 | heating rods for abrasives | 5 pcs |

| 7 | copper feeler gauge | 1pcs |

| 8 | die adjusting bolts | 5 pcs |

| 9 | Feeding spring for feeding machine | 2 pcs |

| 10 | Pe pipe for feeding machine | 2 pcs |

| 11 | air pipe connectors | 5 pcs |