Wood and Plastic PVC Foam Board Production Line

Introduction

Wood And Plastic PVC Foam Board Production Line/

Plastic board extrusion line is used to produce plastic board with width from 600 to 1250mm, which are effective、safeCapacity: Conical twin-screw extruder, suitable for process PVC powder with high capacityDiameter: We have very successful production experience.Auxiliary machine closely meet customer specifications. Nice apperance, automatic control and stable running performance.

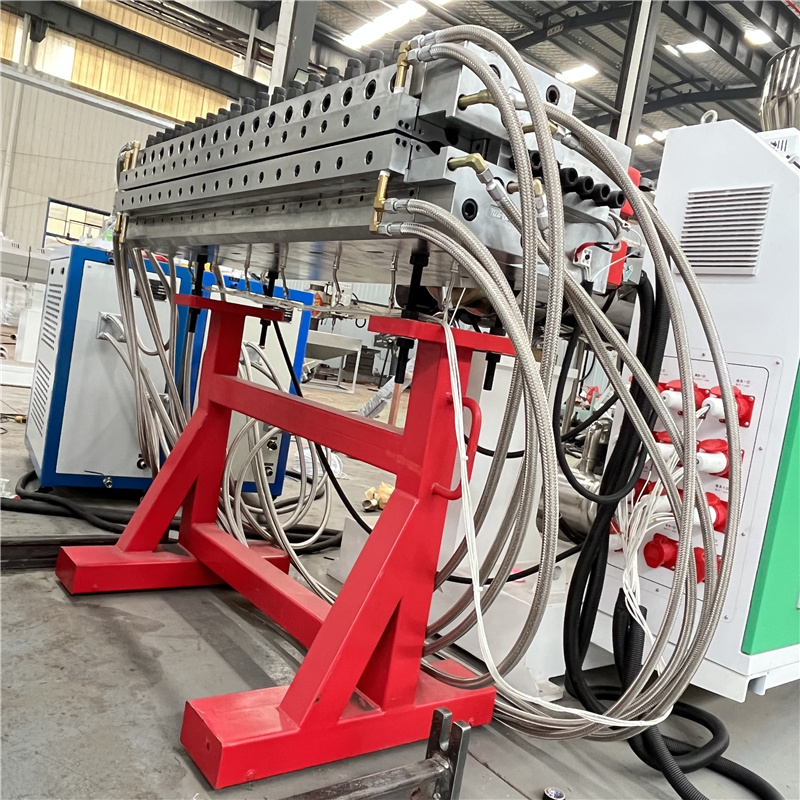

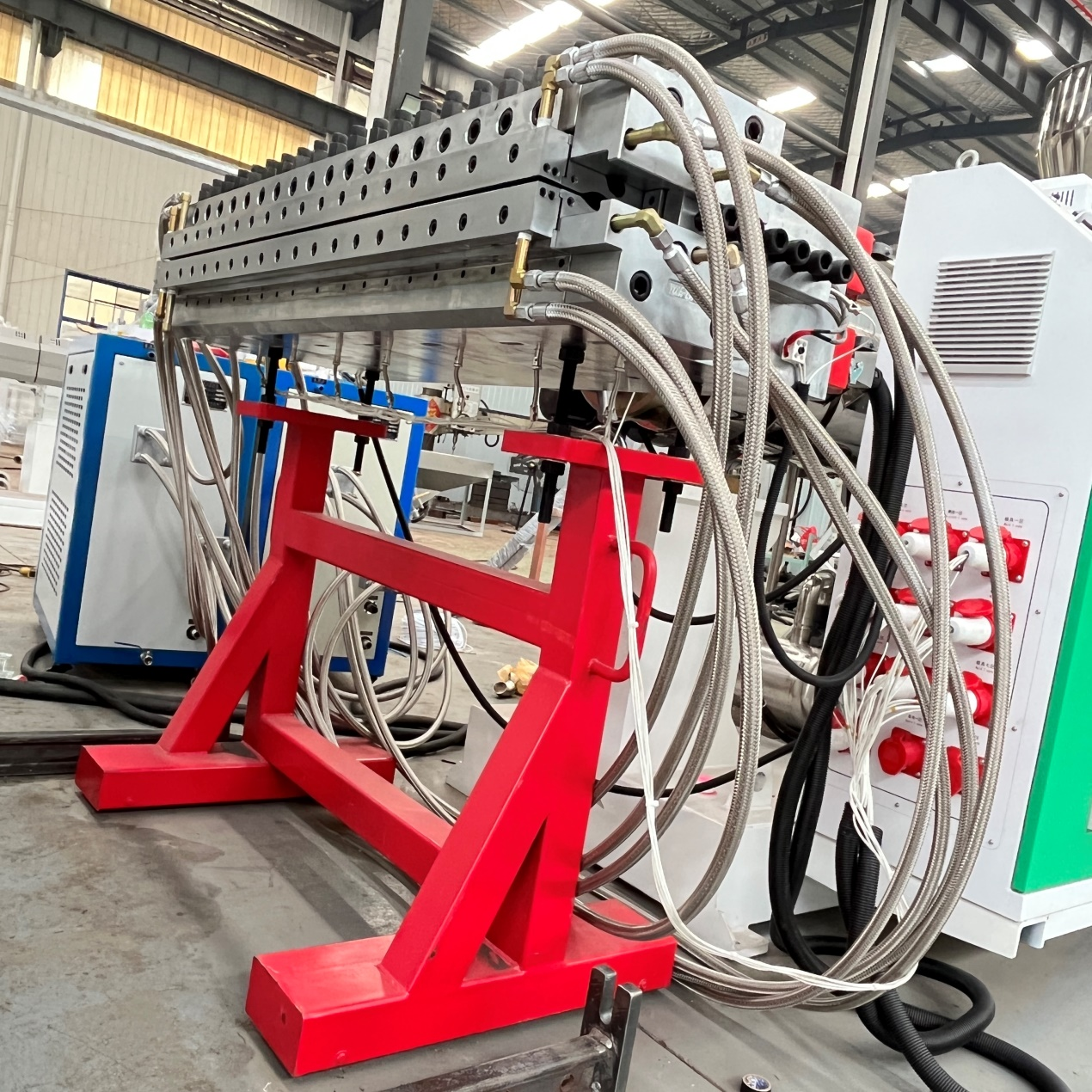

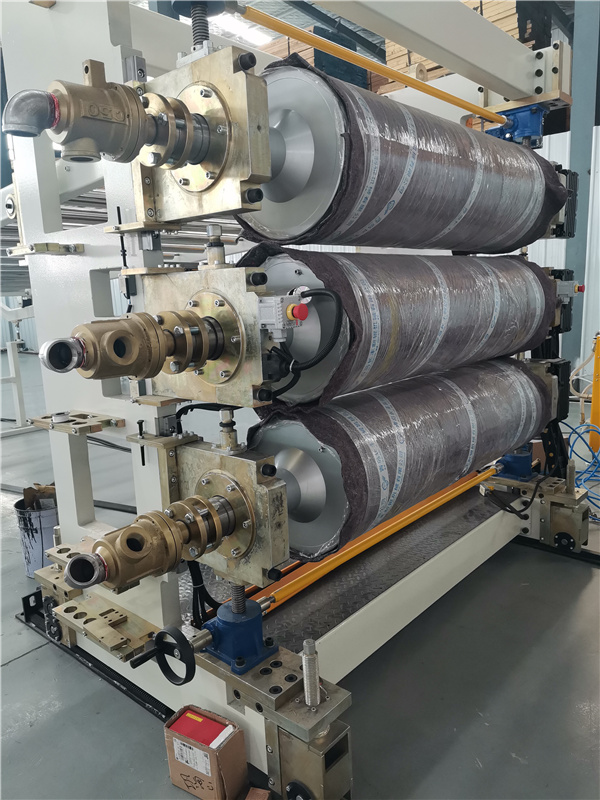

PVC/WPC board machine can continuously produce PVC WPC foam board.This production line is composed of extruder, mould, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.

The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

Our PVC Foam Core Board Production Line Machine

includes the special Twin-screw extruder, mould and other auxiliary machines. Our factory use twin-screw extruder with compact structure, superior performance. Besides the screw and barrel and die are designed by our company and made in world famous manufacturers. And use the high-performance alloy steel for professional processing. So the machine has the advantages of uniform plasticizing, stable extrusion, high output, and long life. We can supply you the best material formulation and all of technology. We have several thousand kinds of formula through 15 years' researches. PVC or WPC foam board production line with big output, stable extrusion, high foaming, good and wear-resisting surface and so on.

|

Machine List |

|||

|

No. |

Name |

Qty. |

Remark |

|

1 |

Screw loader for extruder |

1 |

|

|

2 |

SJZ 80/156 conical twin screw extruder |

1 |

|

|

3 |

Extrusion mould unit |

1 |

1220*2440 |

|

4 |

Vacuum calibration Table |

1 |

|

|

5 |

Cooling bracket |

1 |

|

|

6 |

Haul off unit |

1 |

|

|

7 |

Edge cutting device |

1 |

|

|

8 |

Tracking cutter |

1 |

|

|

9 |

Automatic shift machine |

1 |

|

|

10 |

Dust collection device |

1 |

|

|

11 |

Mould temperature controller |

1 |

|

|

Auxiliary Machine |

|||

|

12 |

SRL-Z Series Mixer unit |

1 |

Capacity : 450-550kg/h |

|

13 |

Screw loader for Mixer |

1 |

|

|

14 |

Crusher |

1 |

Power: 11kw,22kw,30kw |

|

15 |

Pulverizer |

1 |

Power: 45kw,55kw,75kw |

Extruder model

| Item | SJSZ 65/132 | SJSZ 80/156 | SJSZ 92/188 |

| Screw Diameters(mm) | 65mm/132mm | 80mm/156mm | 92mm/188mm |

| L/D Ratio | 22:1/25:1 | 22:1/25:1 | 22:1/25:1 |

| Output(Kg/h) | 160-200 | 250-350 | 400-500 |

| Main Driving Power(kw) | 37 | 55 | 110 |

| Heating Powder(Kw) | 4 zones, 20Kw | 5 zones, 38Kw | 6 zones, 54Kw |

Application

Interior decoration: furniture board, door board, bathroom cabinet, kitchen cabinet, home decoration board, various household shelves, office board;

Advertising industry: screen printing, computer engraving,ad board, exhibition plate, log plate;

Transport industry: ship/plane/bus and train floor covering, core layer, indoors decoration plate;

Building Industry: construction template, rot proof project in chemical industry, thermal shaped part, insulation board, special cool-keeping protection plate.