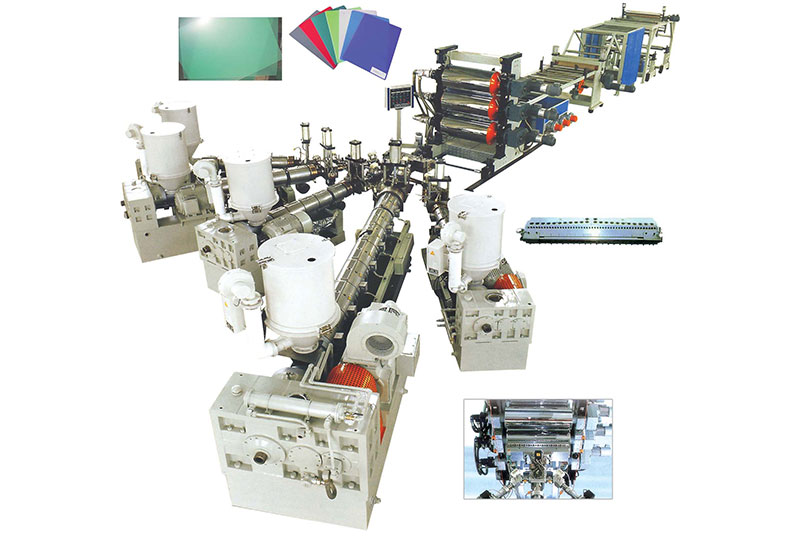

Multi-layers co-extrusion plastic sheet board extrusion line

Basic Information

1.SJ120 single screw extruder

2.SJ90 single screw extruder

3.Automatic Hydraulic Quick Screen Changer Two sets

Performance features:

- Double-Station Quick Screen Changer enables the changing of screen within 2 seconds or below.

- The automatic screen changer can change the screen in a timely, prompt and reliable manner to ensure the constant and continual output of materials.

4. Co-ex extruding die mould One set

Performance features:

- Coated with chrome & polished

- Alloyed mould steel material

- Casting Alluminium heating band

| Width of mould | mm | 1600 | |

| Sheet thickness | Min. | mm | 0.5 |

| Max. | mm | 5 | |

| including | Die head Die pain Die bushing Heating band & support trolley |

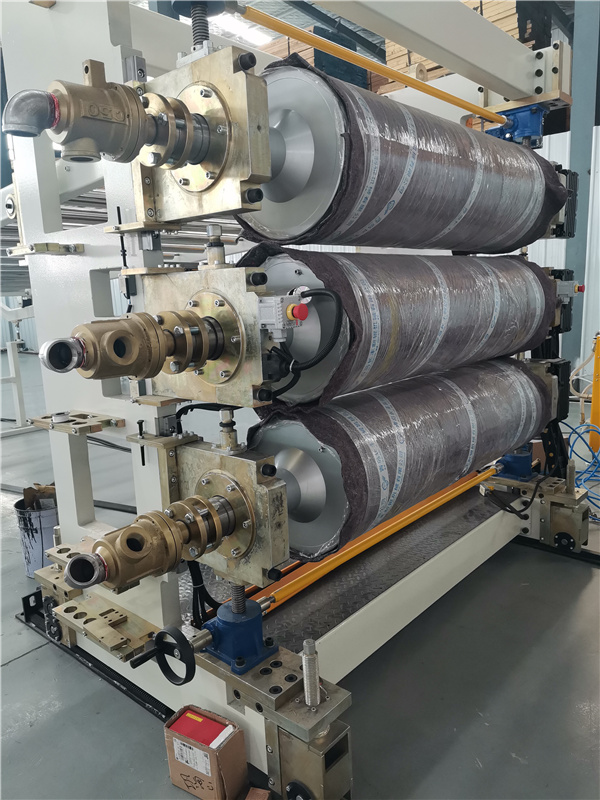

5. Three roller Calender and side cutter One set

Performance features:

- With emergency stop

- Adjusting method the roller space: Pneumatic adjusting

- Temp-regulating of roller: water-heating and cooling

- Blade method side cutting

- Low energy consumption

- Low noise design

| Product Width | mm | 1600 | |

| Ready products thickness, or gap | Min. | mm | 0.5 |

| Max. | mm | 5.0 | |

| Roller diameter | Upper roller | mm | Ø400 |

| Middle roller | mm | Ø400 | |

| Bottom roller | mm | Ø315 | |

| Roller length | mm | 1600 | |

| The thickness of chrome surface | mm | 0.1- 0.12 | |

| Surface chrome conditions | class | 12 | |

| No. of rollers | Pcs | 3 | |

| Max. Linear speed | m/min | 15 | |

| Driving motor power | kw | 2.2 | |

| Driving motor quantity | Pcs | 3 | |

| Moving motor power | kw | 0.75 | |

| Max. elevating dist. Of upper or bottom roller | mm | 50 |

6. Bracket and Haul-off Machine One set

Performance features:

- A pair of rubber rollers haul off

- Speed adjustable control, the up and down rollers are synchronized via drive unit

- With emergency stop

- Low energy consumption

- Low noise design

| Dia. Of sloe-cooling roller | Mm | Ø70 | |

| Length of sloe-cooling roller | Mm | 1700 | |

| Dia. Of towing roller | Mm | Ø160 | |

| Length of towing roller | Mm | 1700 | |

| Towing linear velocity | Min. | m/min | 2 |

| Max. | m/min | 20 | |

| Towing motor | kw | 2.2 | |

| Width without edge | mm | 1500 |

7. Cutter One set

Performance features:

- The machine is manufactured according to EU Norms.

- Adjustable machine leveling feet.

- With emergency stop.

- Low energy consumption.

- Low noise design.

| Method | Balde cutting | ||

| Thickness of the sheet | Min | mm | 0.5 |

| Max. | mm | 5 | |

| Width of the sheet | mm | 1600 | |

| Method | Electric |

8. Stacker (up and down platform) One set

Performance features:

The cut sheets are transported to the up-down platform, whish can adjust the height according to the quantity of the sheets. When the sheets reach a certain quantity, they’ll be put down by the stacker for packing.

| Technical data | Unit | Details |

| Production width | mm | 1600 |

| Motor Power | KW | 1.1 |

| Length | mm | 2500 |

| Width | mm | 1700 |

| Height (can be adjusted ) | mm | 600~1000 |