Plastic Board Extruder PVC Skinning Foam Board Extrusion Machine

Raw materials used in manufacturing:

PVC material + plant fiber(wood power, rice chaff etc)+necessary chemical ingredient

Process flow:

1. Wood > Wood powder > (wood flour dryer)

2. PVC material + wood flour + necessary ingredient > WPC mixing equipment--> WPC board Extrusion Line-->WPC board profile-hot transfer printing

PVC Surface Crust Foamed Board Production Line

PVC Skinning Foamed Board Production Line/ PVC Skinning Foam Board Extrusion Machine

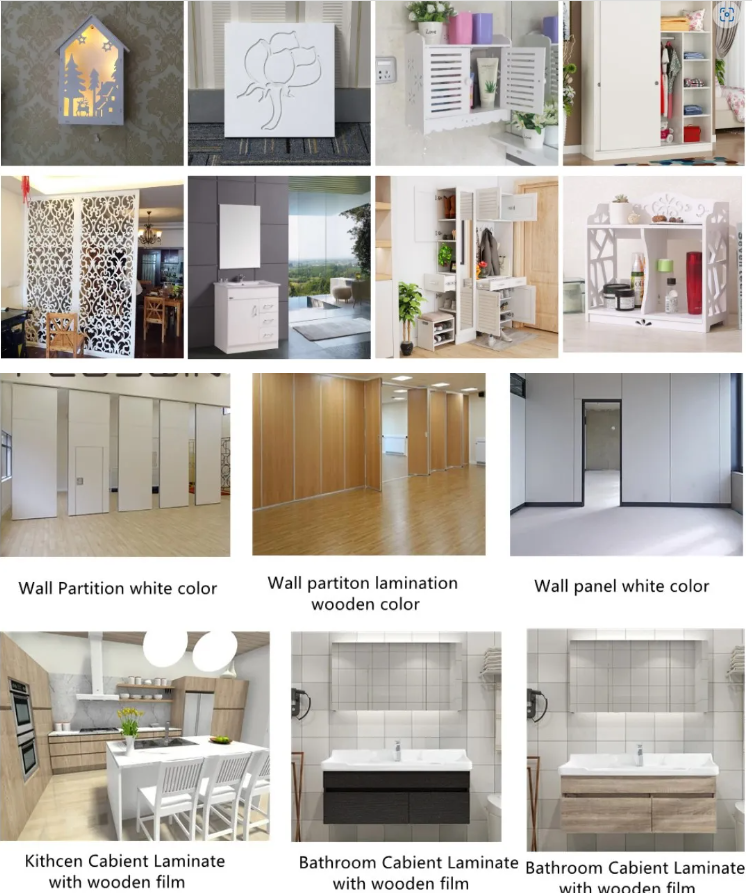

WPC/PVC foam board extrusion line is Used to make construction panel, decoration panel, balustrade, pavement, steps, outdoor tables, wall panel and chairs, pergola, tree bed, etc. Material: 30-60% straw, wood flour, rice chaff mixed with recycled PVC, PP, PE powder. Indecomposable, deformation free, fade resistant, insect damage resistant, good fireproof performance, crack resistant, and maintenance free etc.

PVC WPC Sheet is a new material for both inside or outside decoration. It has hard and smooth surface, which can be laminated by various materials such as PVC film, impregnated paper, etc. It opens a new world of decoration, the laminated board is not only waterproof, UV resistant and anti-corrosion, but also special and beautiful. WPC sheet is like wood, but it is much better than wood.

Work flow

PVC powder +additive → mixer →SJSZ series extruder →Coat-hanger type mould →Vacuum calibration cooling platform →cooling rollers and edge-cutting device →Haul off →stacker

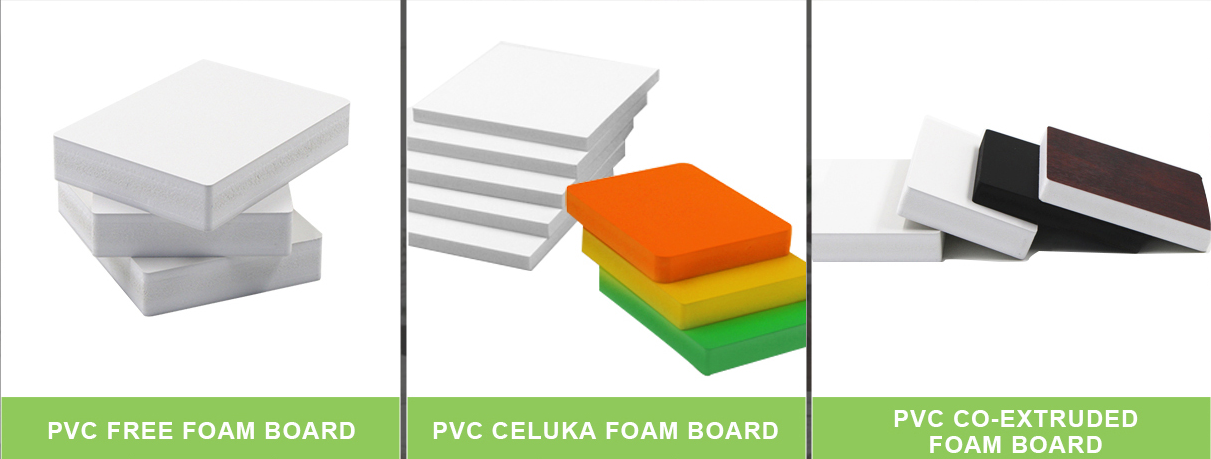

The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

Output dimension of long life PVC foam board machine

|

Extruder Mold |

|

SJSZ-80/156 |

SJSZ -80/173 |

SJSZ -92/188 |

|

Output capacity |

kgs/h |

350 |

550 |

650 |

|

Output thickness |

mm |

3-25 |

3-30 |

3-30 |

WPC Foam Plastic Furniture PVC Kitchen Cabinet Board Making Machine

Q1: Your company is a trading company or a machine manufacturer?

A1:Our company is a plastic machinery manufacturer which is engaged into this trade more than 10 years.As a manufacturer,we could supply our machine,service,technical support and maintenance directly and it is more convenient.

Q2:How to get an accurate offer?

A2:Because our offer and technical specification is associated with your final product and requested capacity,we will choose the right model of extruder and mould after understanding all the information,then we could supply our plan.We could fully exchange information by Email,whatsapp or wechat.

Q3:Where is your factory and which port is the nearest to your factory?

A3:My factory is in Qingdao city,Shandong Province and it would take about 25minutes from our factory to Qingdao jiaodong Airport.

The nearest port is Qingdao port.

Q4:How long is the delivery time?

A4:Generally it will take 35-45days.

Q5:Could you send your engineers to our factory?

A5:Yes,we will send our engineers to your factory for installation,commissioning and training after machines arrive at your factory.In addition,if you need our engineers available in the future,we also could send our engineers.