-

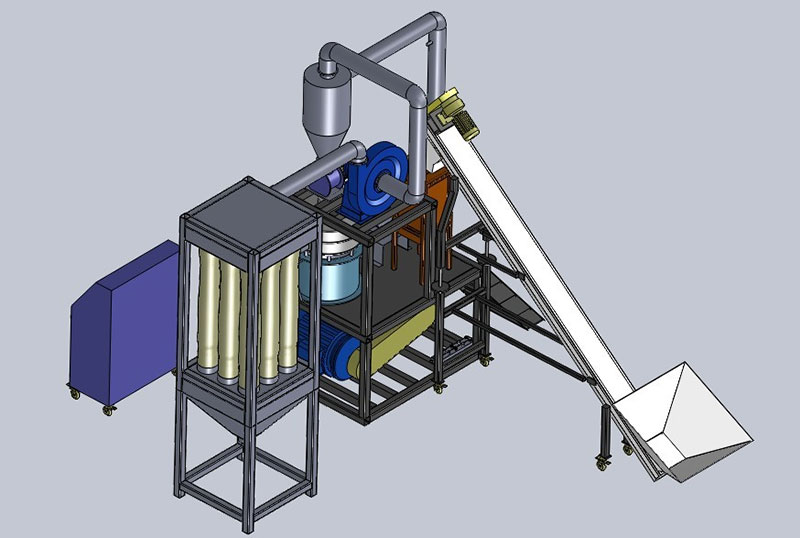

Plastic Grinding Mill pulverizer

Plastic Recycling Machine:SMP series belongs to the Turbo-type pulverizer for hard pvc.Different number of blades can be configured according to the size of grinding cavity.It is mainly for hard PVC,ABS, EVA,PVC pipe ,plastic profile and so on.Rigid PVC Pipe Pulverizer/Miller/Milling Machine,we have model SMP400.500.600 PVC UPVC CPVC Pulverizer Machine to Make Powder

-

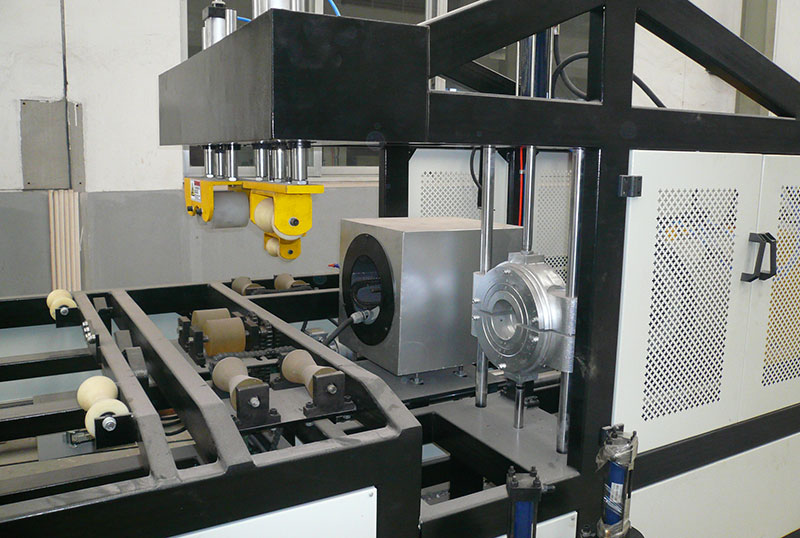

Plastic Crusher/ Shredder

Plastic Crusher / Grinder / Granulator / Shredder Grind PVC Pipes,High quality waste shredder/plastic crusher machine is used to crush plastic, rubber, fiber, paper, wood, large hollow materials (large containers such as plastic drums) and various mixed wastes, especially those containing metal, or pre-crushed tools such as sand. scrap. The crushing hollow material can be equipped with a press device to increase the output. A rotating screen can also be added to control the discharge size. When the double shaft shredder is running at low speed, noise and dust can reach high environmental standards.

-

Pelletizer/pelletizing recycling machine

100-1000kg/H Waste PP PE BOPP Plastic Film Jumbo Bag Regrind Plastic Scraps Pelletizer Two Stage Plastic Crushed Granulator Machine

This plastic granulator machine for waste plastic recycling is used to make plastic flakes into pellets or granules.

And Double stage pelletizing line is especially good for the raw material which contains high moisture, high impurities.

The first stage extruder adopts exhaust type barrel screw, which can effectively de-gassing and eliminate the moisture and contamination;

And the second extruder usually adopts small L/D extruder, further plasticizing the material and filter contamination which can achieve stable extrusion. -

Injection Molding Machine and mould

Injection Molding Machine and mould,We are manufacturing different types of injection molding machines and range starts from 50 Ton to 3300 Ton.

The formwork structure adopts the European style design, the comprehensive optimization parameter and the force distribution, the frame USES the high rigid material and the manufacture craft, guarantees the complete machine solid, the stability is reliable.Simple and easy operation High precision,high speed,stable ,low noise Strong rigidity, reliable and durable

We sell injection machines of different tones, different sizes, different model: hybrid type, hydraulic type, all-electrict type injection molding machines.

-

Chiller

About industrial water chiller ,chiller we hve two kinds :air cooling chiller and water chiller cooling., it depends on match extrusion line capacity, for example PVC foam board machine we suggest use model 20P chiller,

-

Automatic Online PVC Pipe Belling Machine

Plastic Pipes Auto Belling-Machine Specifications

pipe belling machine

machine for expanding plastic pipeDetailed Product Description

PVC pipe belling machine/PVC pipe automatic belling machine is used to expand the end of PVC pipe for connection. It can do two shape, “R” mouth and “U” mouth. and formachine, there are two kind, one is full automatic, another is semi-automatic. -

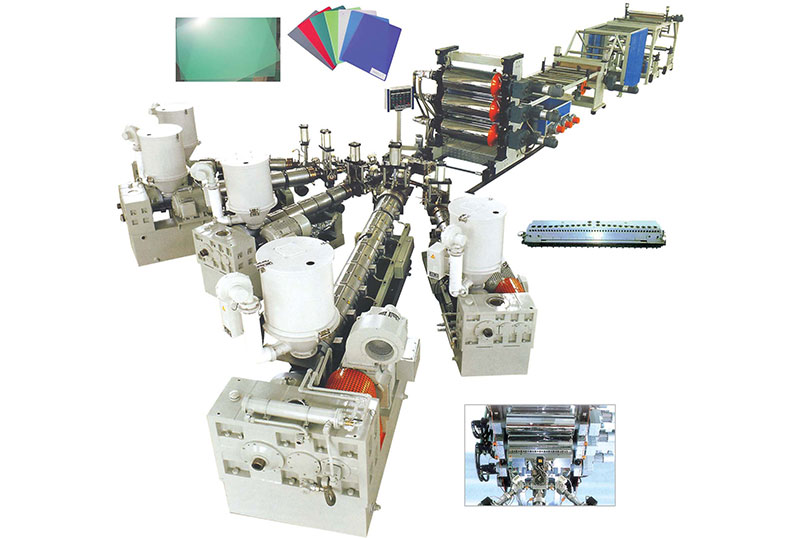

PE PP ABS Sheet board Extrusion Machine

Plastic PP PS HIPS PET ABS Sheet Extrusion Production Line :This production line consists of single screw plastic extruder, vacuum automatic feeding unit, dehumidifiers drying hopper, sheet die, 3 roller-ray unit, heating and leveling unit, roll cooling unit, edge cutting unit, traction, shearing unit, roller conveyor unit. With the characteristics of compact structure, superior performance, Screw and barrel optimized design and use of high-performance alloy 38CrMoAiA professional processing which ensure that the whole production line uniform plastics hand stable extrusion, high yield, long life and other advantages. The barrel uses casting aluminum heater heating, wind cooling and precise electronic temperature control instrument; Precise sizing and roller-ray unit to adjust the template good shape; Cutting unit adopt the fixed-length cutting to ensure the accurate length.

-

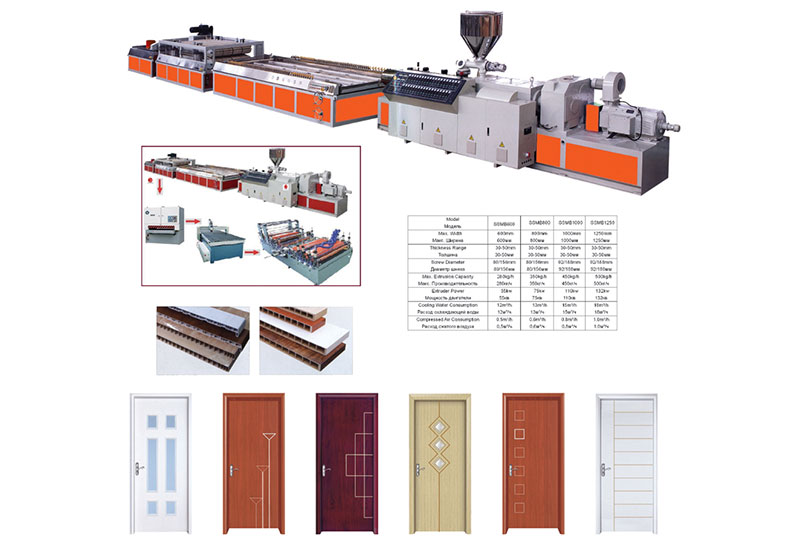

Wood Plastic WPC door board Production Line

WPC PP PE PVC Wood Plastic Profile / Decking/Door Frame/ Wall Panel/Floor Fence Post Window Extruding Extruder / Extrusion Making Machine Factory Price

Screw Loader for Mixer—High Speed Mixing Unit—Screw Loader for Extruder—Conical twin screw extruder—Mold—Vacuum calibration machine—Traction Machine—Cutting Machine—Stacking Table

-

Wood Plastic Composite Profile Production Line

PVC WPC Door Floor Decorative Profile Board Panel Extrusion Production Line ,

Double Screw Profile Extruder This production line is mainly used to produce PVC profile, such as Ceiling, Deck, Floor, Cornice, Plank, Windows, Door frame and board and etc.

Feature:

1. Conical twin-screw extruder, suitable for processing PVC powder and WPC raw materials.

2. Changing the moulds to produce many kinds of different PVC profiles.

3. Auxiliary machine: Mixing unit, Crusher, pulverize, laminating machine… -

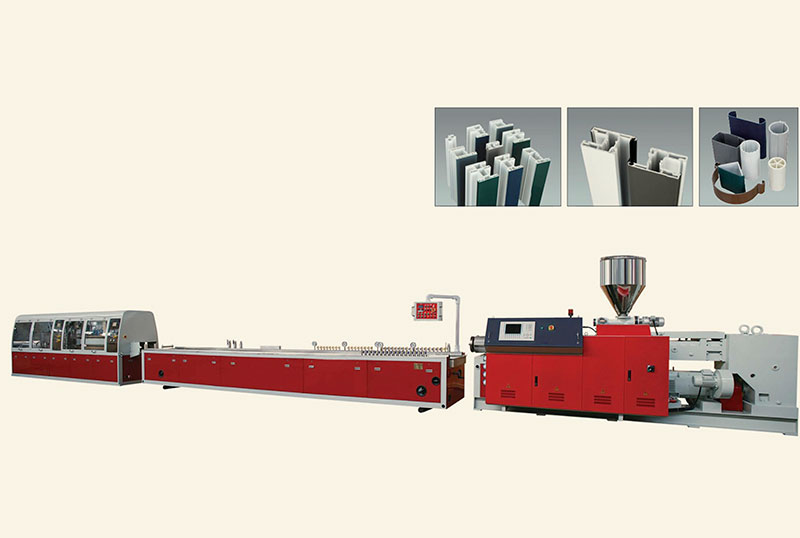

PVC Door and Window Profile Extrusion Line

High Efficiency PVC Window and Door Profile Extrusion Making Machine Production Line ,PVC Profile has such characteristics as sound separation, sound absorption, heat separation, temperature-keeping ,etc. The material is incombustible, it is safe for use.

All series of products have property of moisture proof, mildew proof, water resistance, its vibration resistant effect if good. All series of products have property of weathering proof, its luster may remain forever, it is not easy to be ageing. This product is light, storage & transport, construction are rather convenient. This product can be worked with normal tools for wooden material. Drilling, sawing, nail, planing, bonding can be conducted like wooden material. It is suitable for thermal shaping, thermal bending and fold processing. It can be welded, it can also be bonded with other PVC material. The surface of this product is smooth, it can be printed.(Clean the surface before printing.)

-

Plastic PVC Electrical Cable Trunking Profile Extrusion Line

Plastic Cable Trunk Profile Extrusion Line Plastic Extrusion Machine ,Plastic PVC Electrical Cable Trunking Profile Extrusion Line

>> Use:For production of soft PVC profile, rigid PVC profile, soft-hard co-extrusion profile,foam profile extrusion, multi layer co-extrusion etc.

>>Process Flow: Screw Loader →cone / parallel Twin Screw Extruder/Single screw extruder → Co-extrusion machine → Mould →Calibration Table → Haul-off & Cutter →Tripping Table → Final Product Inspecting & Packing -

PET packaging strap belt production line

- Plastic PP Pet Packing Band Strap Belt Extruder Making Machine

Packing Band Making Machine

Pack Band Extruder

Plastic Pet Packing Strap Belt Making Extruding Machine

Plastic Strap Making Machine

Pet Strap Extrusion Machine

PET Plastic Strap Packing Belt Making Machine

pet belt extrusion machine

Plastic PP Pet Packing Strap Making Line Pet Strapping Banding Belt Strip Production Machine

PP Strap Making Machine

PP Strapping Band Making Machine

Plastic PP Packing Strap Line / Strapping Machine with Cheap Price

Strap Extrusion

Strap Line - What about the output of PET strapping band extrusion line? 200kg/hr, 400kg/hr, 600kg/hr, 800kg/hr.

- What about the size of strap that the PET strap machine can make? Width: 9-32mm; Thickness: 0.35-1.2mm;

- What about the installation power of the PET strap machine? 215kw/285kw/352kw/900kw;

- What about the maximum tensile strength of the strap? 12000N (32*1.2mm);

- What about the camber of strap? <20mm/2m;

- What about the usage of PET strap? Packing cotton, aluminum, wood, brick, boxes;

- Will the strap be used for automatic strapping tool or manual tool? Both.

- Plastic PP Pet Packing Band Strap Belt Extruder Making Machine