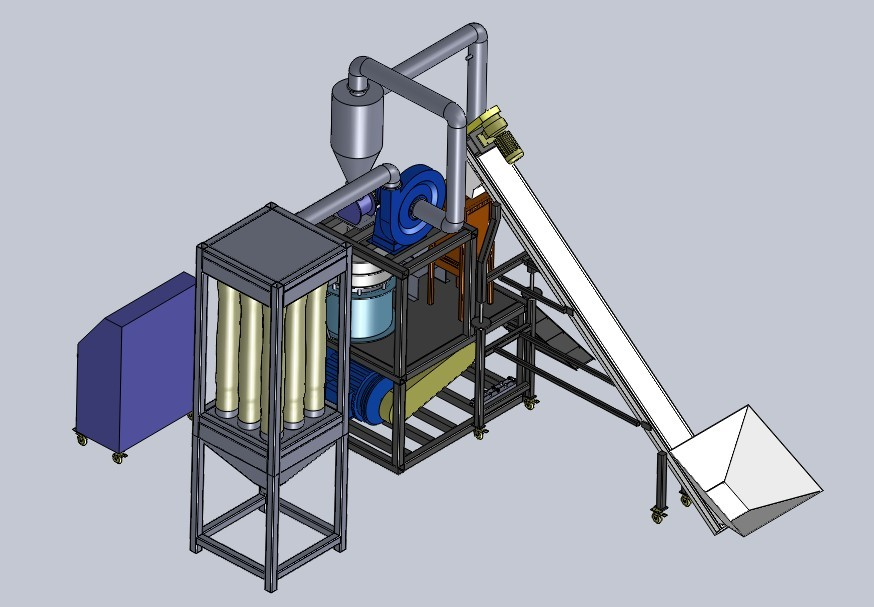

PVC milling pulverizer

Advantages

● Save and simple adjustment of cutting gap

● Low drive power and High throughput

● Innovative efficient design

● Easy to maintain and control

● Wide range of accessories

● Automatically regrinding coarse powder

● Dual cooling system

Product parameters

SMP 500PVC Miller/grinder

- Capacity: 200-300kg/h

- Main Motor Power: 45Kw

- Motor brand: chin FAMOUS BRAND

- Main Shaft Speed: 3800rpm

- Fixed knife: 12 pieces

- Rotating knife: 24 pieces

- Knife’s materials: SKD-11

- Cooling Method: Water cooling

- Fan Power: 5.5Kw

- Powder size: OVER 60 mesh

- Dust connect: With bags to connect dust. To protect the environment

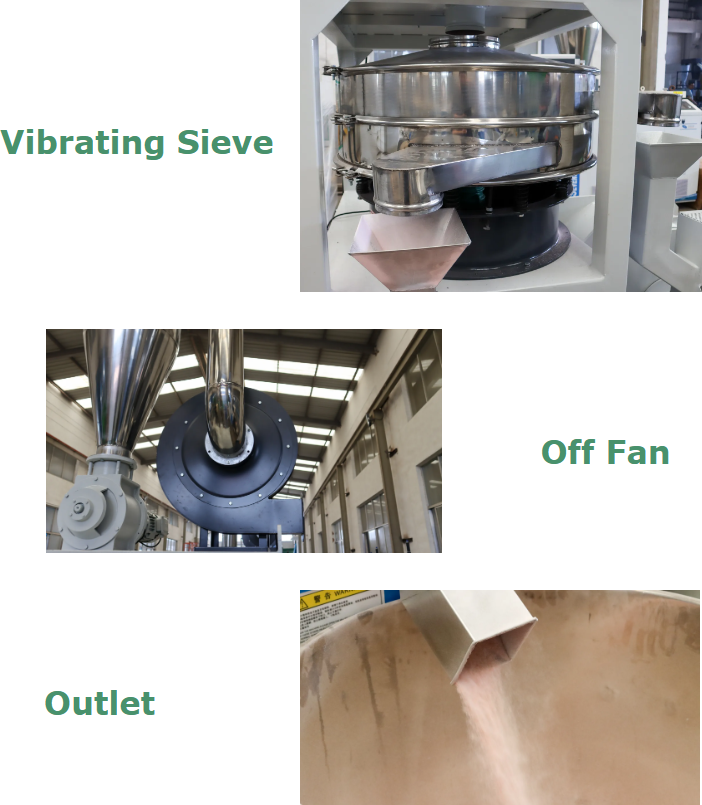

- Vibration Sieve Type: ZDS1000

- Screw conveyor to convey material from ground to vibration feeder.

|

Model |

MF400 |

MF500 |

MF600 |

MF800 |

|

Diameter of milling blade |

400mm |

500mm |

600mm |

800mm |

|

Power |

30KW |

45KW |

55KW |

90KW |

|

Blade material |

SKD-11 OR D53 |

SKD-11 OR D53 |

SKD-11 OR D53 |

SKD-11 OR D53 |

|

Capacity |

150KG/H |

250KG/H |

350KG/H |

450KG/H |

- Power source: 3 phase 380V – 50Hz

- Application: Mill PVC Powder

SMP 600PVC Miller/grinder

The low temperature is the main advantage of the machine

1、 According to the heat work equivalent: after doing work per hour into 860 kcal heat, this machine is external exhaust, the air volume is large, by the import and export of the wind temperature difference on behalf of most of the heat, a small part of the heat is solved by water cooling. Requirements: The inlet temperature of the cooling water is not more than 25, the outlet water temperature is not more than 50, and the cooling water flow is appropriately increased in summer to reduce the temperature。

2、 Third, the main technical parameters

3、 Number of cutter heads: 1 piece, outer diameter 600mm

4、 tooth plate: 1 pay (high-quality steel carburizing quenching, hardness hr60)

5、 Blade: 30 pieces (high-quality steel carburizing and quenching, hardness hr60)

6、 Spindle speed; 3000r/min

7、 Motor power: 55kw

8、 Induced draft fan model: YI32S1 power: 7.5kw

9、 Shutdown fan power: 0.75kw

10、 vibrating screen motor power: 0.25kw

11、 Output: pvc20-80 mesh output 150-360kg/h

12、 Weight: 1200kg