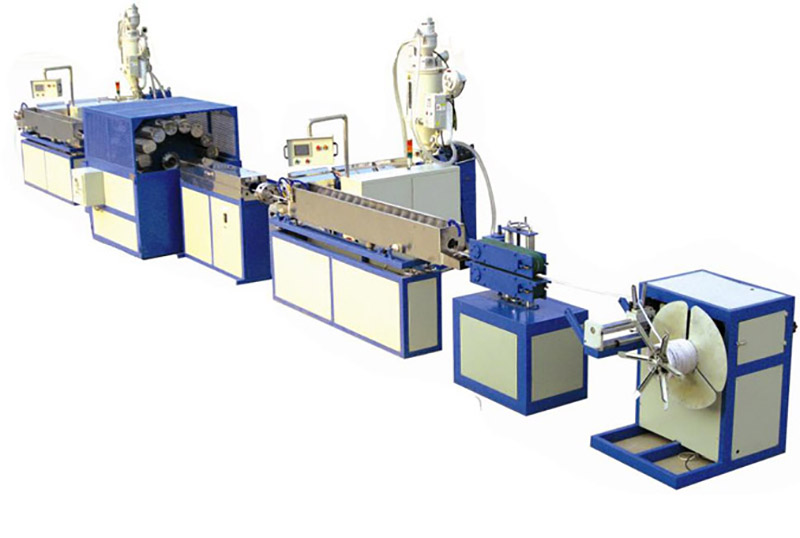

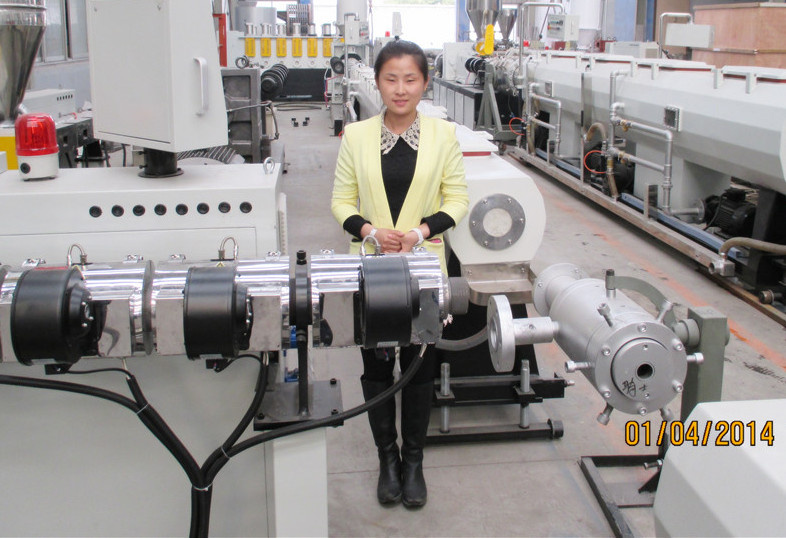

PP,PE coating pipe production line

Product Detail

The main equipment of extrusion line

|

|

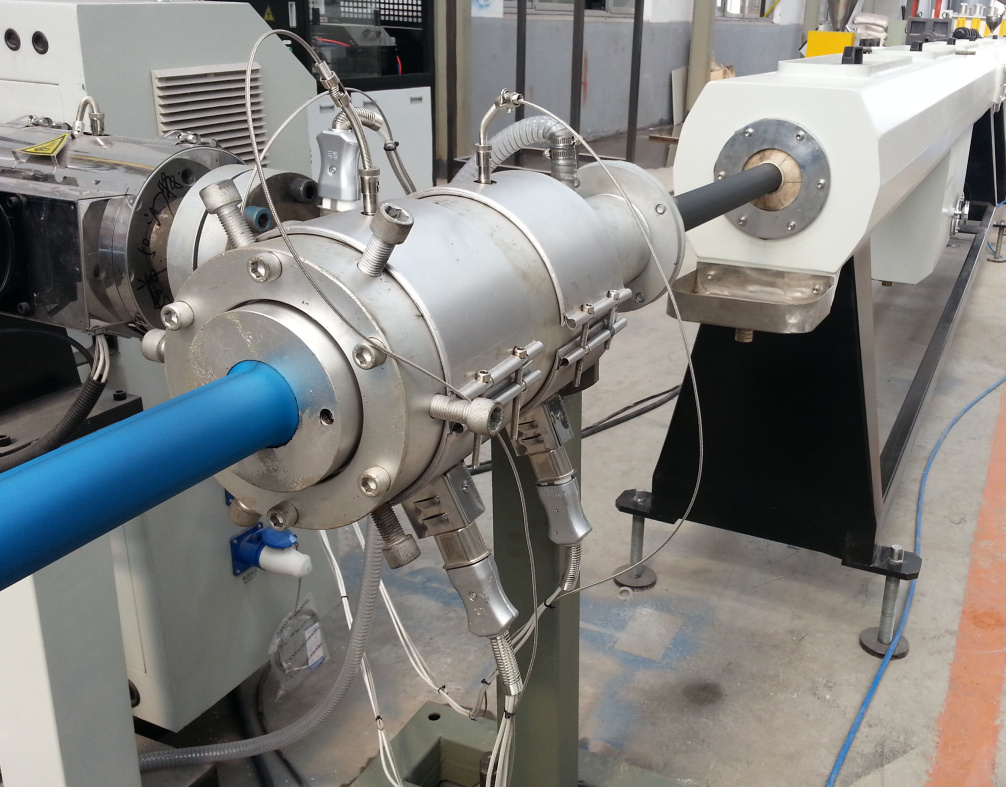

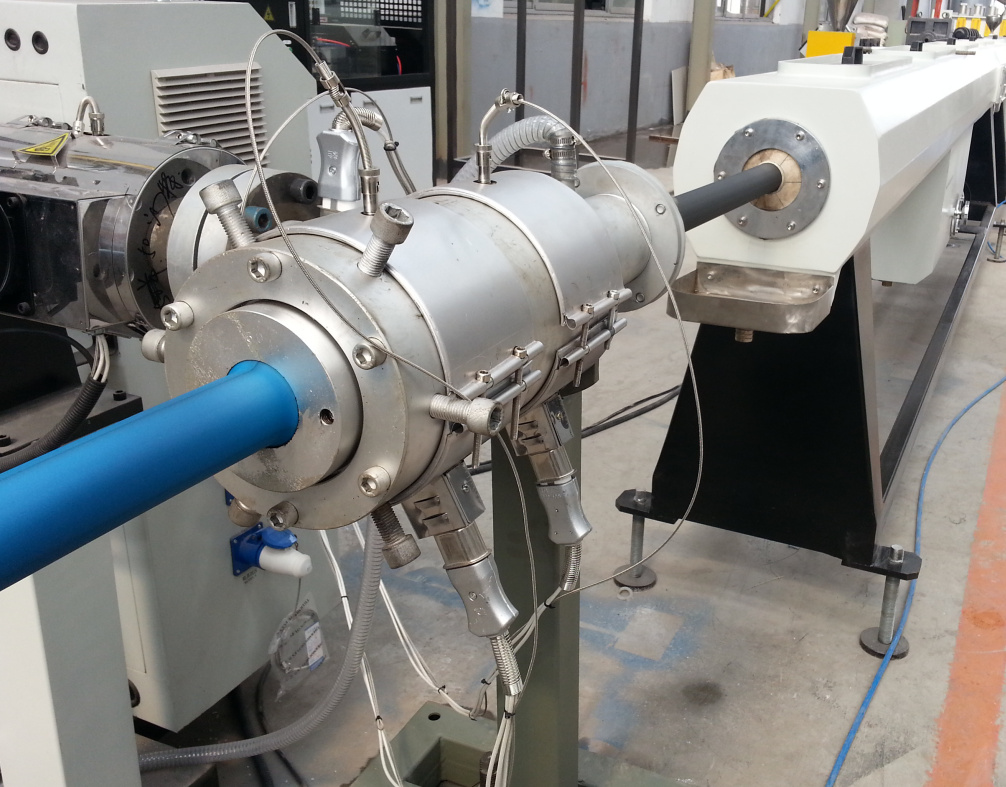

|

|

1 |

SJ-90/33 Single screw extruder with Automatic dry feeding system |

|

|

With SIEMENS PLC English / Chinese menu |

|

2 |

SJ25 single screw extruder for marking line |

|

3 |

die head 16-63mm tp produce pe pipe 16-63mm with high speed design |

|

4 |

Vacuum Calibration unit 9m length |

|

5 |

SJ50 single screw extruder for coating color |

|

6 |

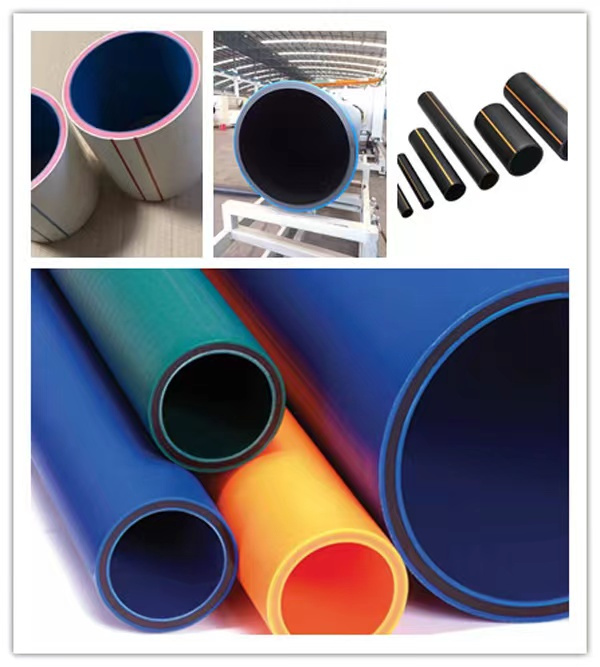

Pe coating color pipe line |

|

7 |

High effective spraying cooling tank 6m length |

|

8 |

High speed Haul-off machine |

|

9 |

High speed non-dust cutter |

|

10 |

Double positon Winder 16-63mm |

|

11 |

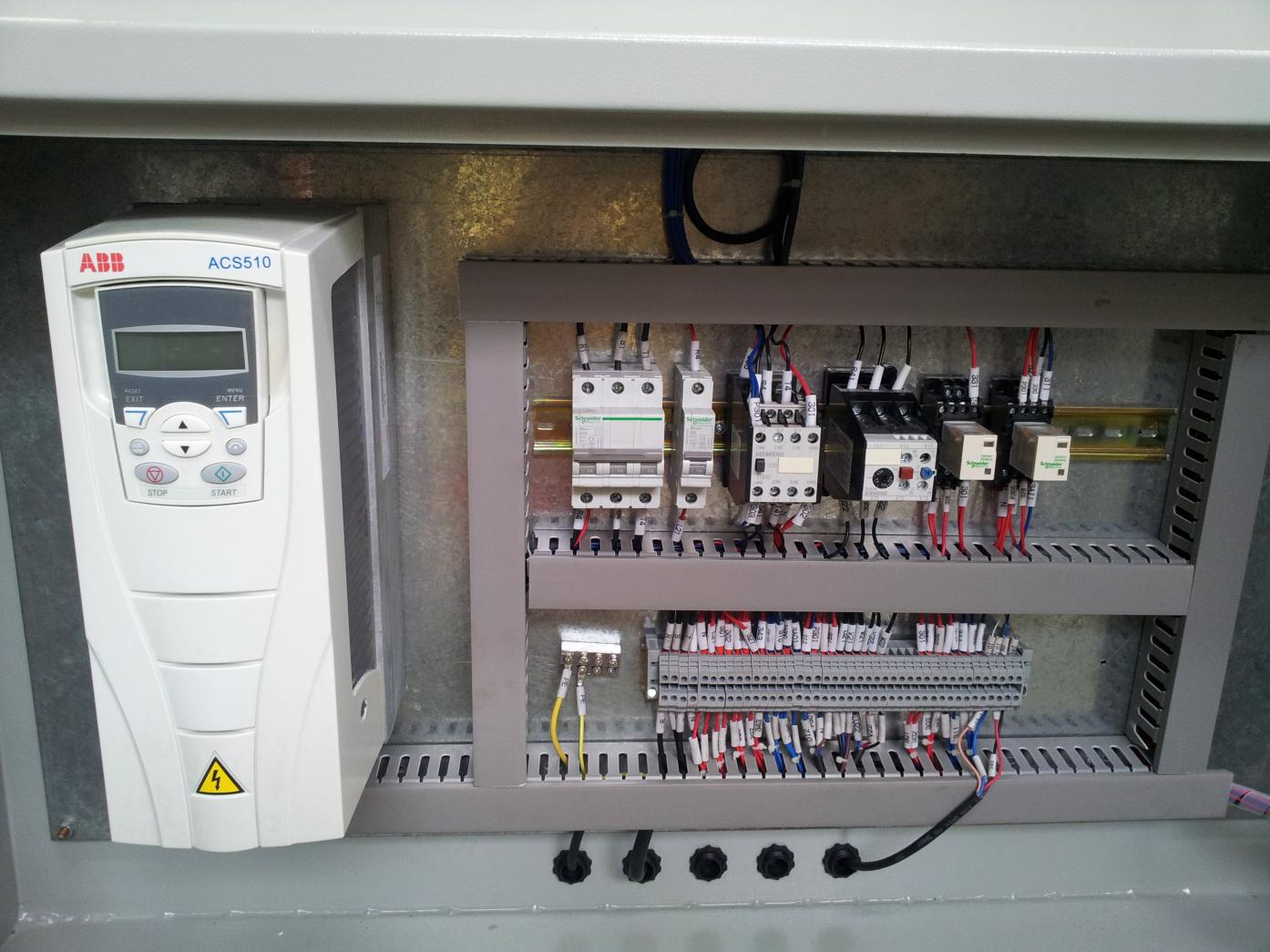

Electrical control system |

|

12 |

Spare parts list |

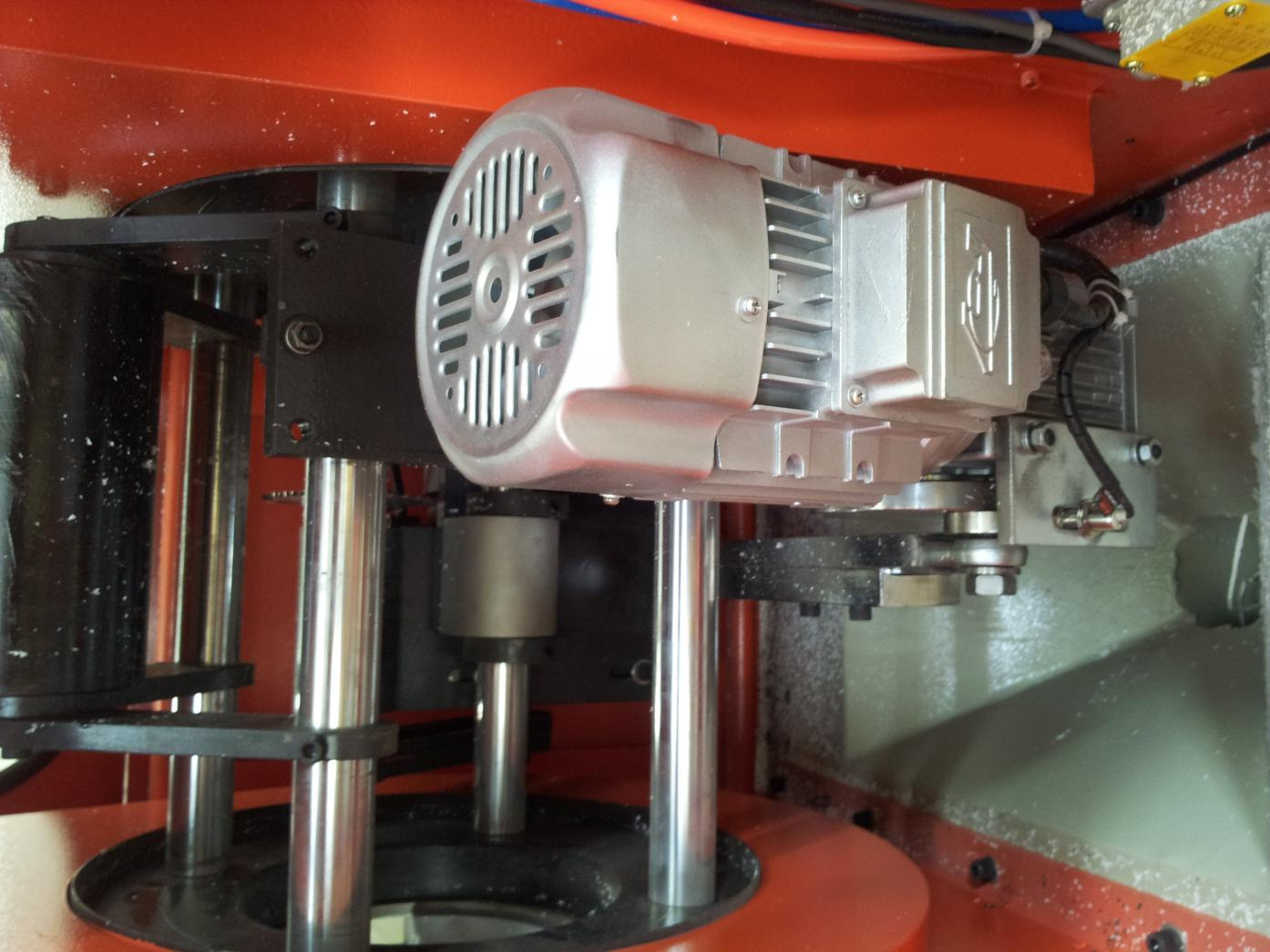

1.SJ-90/33Single screw extruder

With SIEMENS PLC English / Chinese menu

| Screw and barrel | Zhoushan(Jinxing) | |

| Material | 38CrMoAIA | |

| Nitrided layer thickness | 0.7-1.0mm | |

| Screw hardness | HV740 Nlt. | |

| Barrel hardness | HV940 Nlt. | |

| Screw diameter | 90mm | Single screw |

| Screw rotate speed | 120rpm | |

| L/D | 33:1 | |

| Barrel heating method | Stainless heating | |

| Heating zones | 5 zones | AC motor |

| Total power | 40Kw | |

| Heating power | 8KW*5 | |

| Cooling method | Air fan cooling | |

| Power of fan | 5*0.37Kw | |

| Drive motor | AC motor | |

| Power | 132Kw | Gear Box Guomao |

| Gearbox origin | Gear Box | |

| Gears type | Helical gears | |

| Heat treatment | Carburized grind | |

| Connecting method | Directly | |

| Degassing unit | Water-ciecle vacuum pump 7.5Kw | |

2.SJ25 single screw extruder for marking line -4pcs

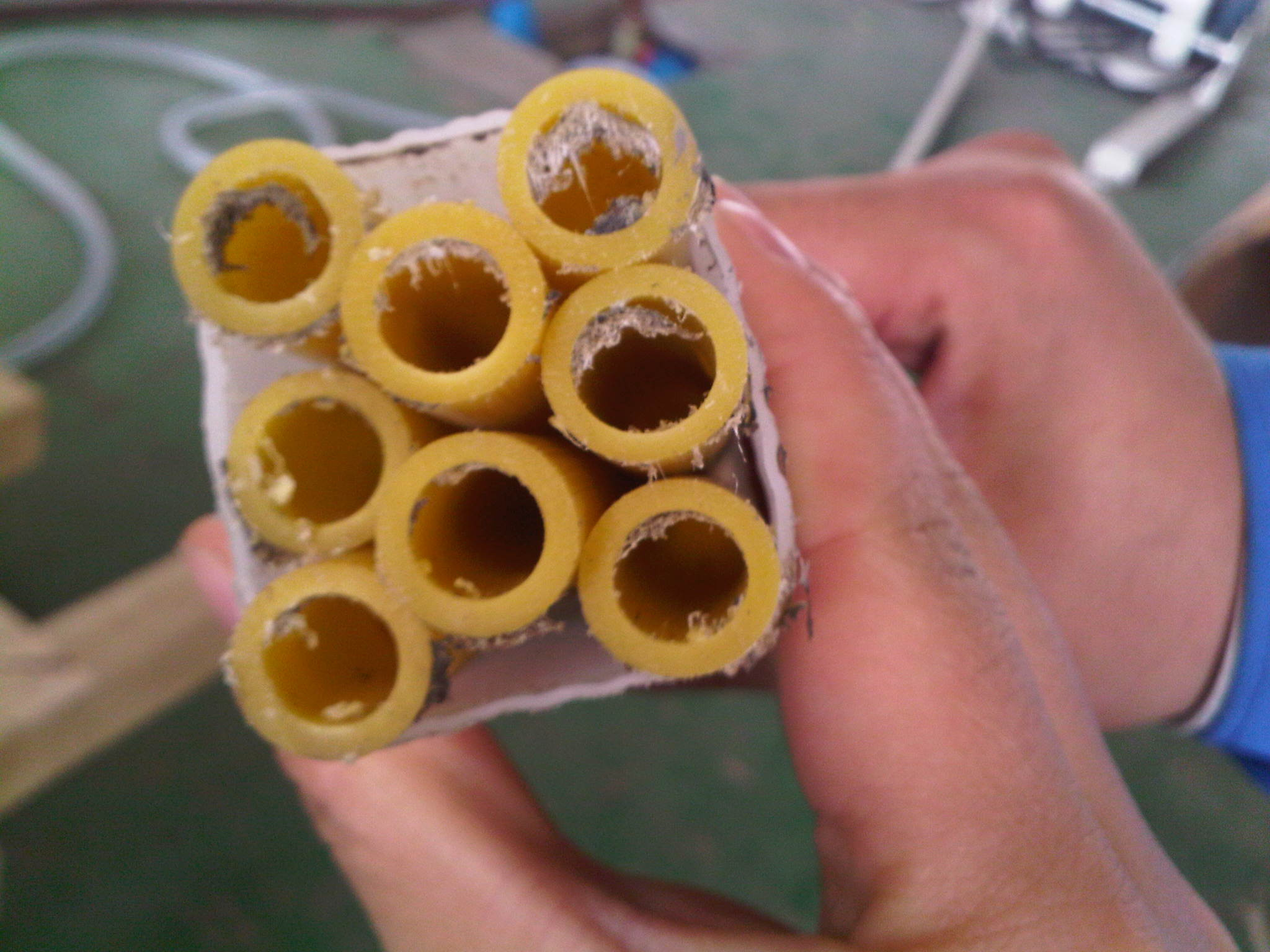

3.High speed design pipe moulds

| Die head range | 16-63mm | |

| Die quantity | One set | |

| Material of Die | 40Cr quenched | |

| Newest technology with Spiral design.Good quality 40Cr steel with Nitrogen quenched to reinforce the quality. Newest design of Die support trolley, with easy adjustable factures

|

||

4.Vacuum Calibration Unit 9m length

|

Central height |

1100mm |

A new generation of vacuum calibrators with convincing features: l Precise temperature guidance l Flow optimized pipe work made of Stainless materials l The unit is equipped with vacuum pump, water pump, forward-backward motor and control box. The system is designed for the controls of water inflow, water level, water temperature, auto water supply, water drainage and pressure release. The unit is fully automatic, which is different from the conventional cooling system. |

|

Moving motor |

AC 0.75 kw |

|

|

Material of tank |

304 # Stainless steel |

|

|

Central height can be adjusted a little |

||

|

With longitudinal moving unit |

||

|

Water pump |

2piece |

|

|

Power of water pump |

5.5kw |

|

|

Vacuum pump |

2piece |

|

|

Power of vacuum pump |

4kw |

|

|

Length of the equipment |

9000mm |

|

|

Width of the equipment |

600mm |

|

|

Automatic control system |

One set |

|

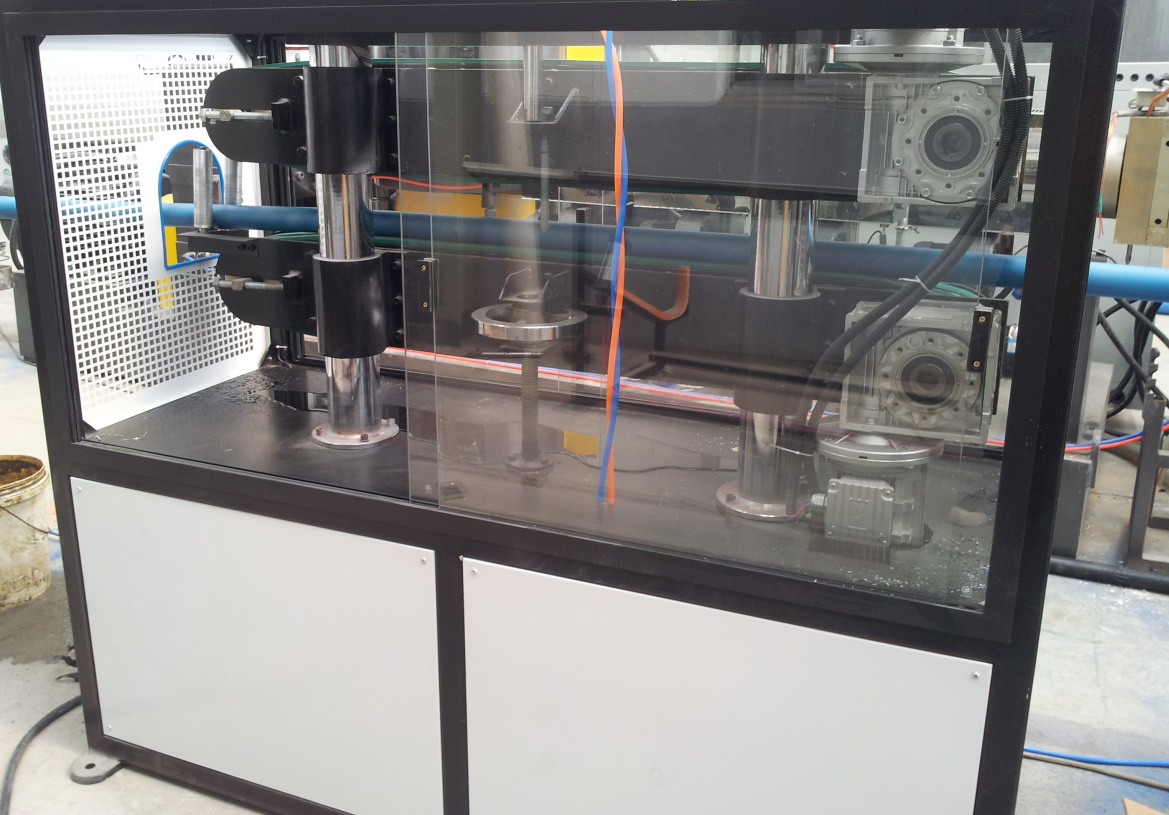

5.SJ50 single csrew extruder with coating pipe mould -high speed design

6.High effective spraying cooling tank

| Central height | 1100mm | The unit is fully automatic.

tank is made of stainless steel, spray nozzles are made of ABS

|

||

| Moving motor | AC 5.5 kw | |||

| Material of tank | Stainless steel | |||

| Central height can be adjusted a little | ||||

| With longitudinal moving unit | ||||

| Method | Enforced spraying | |||

| Water pump | 1 piece | |||

| Power of vacuum pump | 7.5kw | |||

| Length of the equipment | 30m | |||

| Width of the equipment | 600mm | |||

| Automatic control system | One set | |||

7.Haul-off unit with encode

High speed Cutter machine with Siemens touch screen unit

| Function: cut HDPE pipe in fixed length | |||

| 1 | Cutter type | Automatic meter counting cutter | |

| 2 | Suitable cutting pipe diameter | 16-160mm | |

| 3 | Cutting speed | Synchronization, automatic cut in fixed length | |

| 4 | Motor power | KW | 2.2 |

| 5 | Material of Cutting Saw | Alloy steel | |

| 6 | Clamping Mode | Pneumatically Drive | |

| 7 | Cutting Control | PLC control | |

| 8 | Maximum cutting thickness | mm | 18 |

| 9 | Suitable cutting speed | m/min | 12 |

| 10 | Machine dimension | mm | 2100X610X1360 |

Double position winding machine 16-63mm one set

We can do different kinds coating pipe machine