Large Diameter Hollow Wall PE Winding Pipe Making Machine

PE HOLLOW WALL WINDING PIPE.

1) Extremely strong resistance to chemical corrosion and erosion. 2) Good flexibility and strong impact resistance 3) Cold resistance and aging resistance. The connection is simple, safe and reliable. 4) Light weight and convenient construction. 5) Strong wear resistance. The service life is more than 50 years, and it is maintenance-free during the service life. 6) Superior drainage performance. It is hygienic and can be recycled and used.

|

NO |

Name of Commodity & Specification |

Quantity |

|

Host machine |

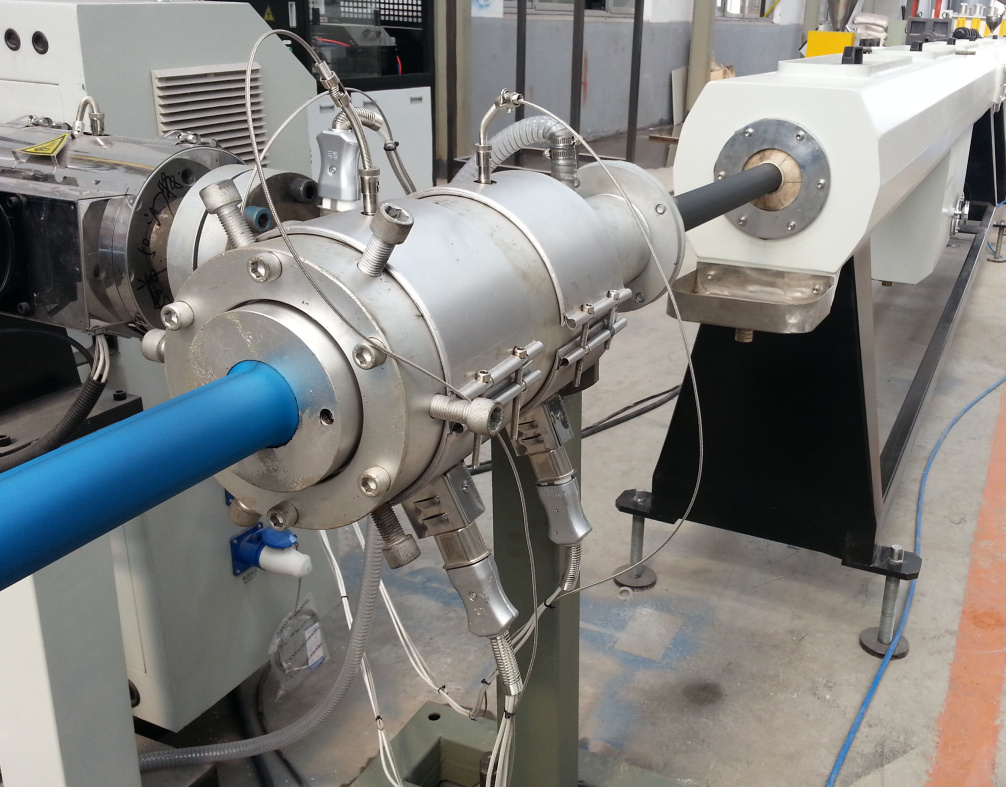

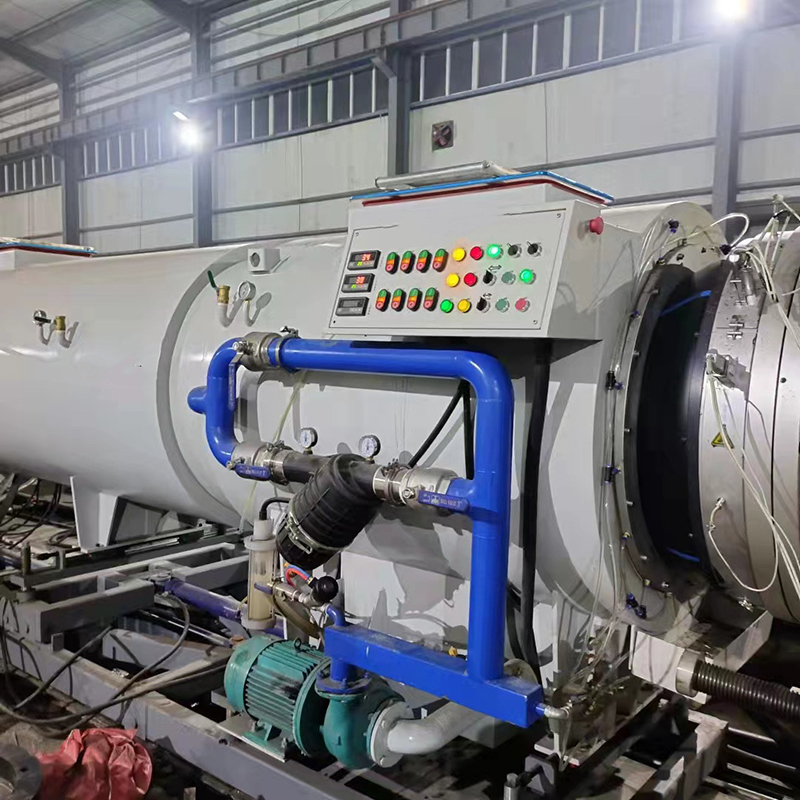

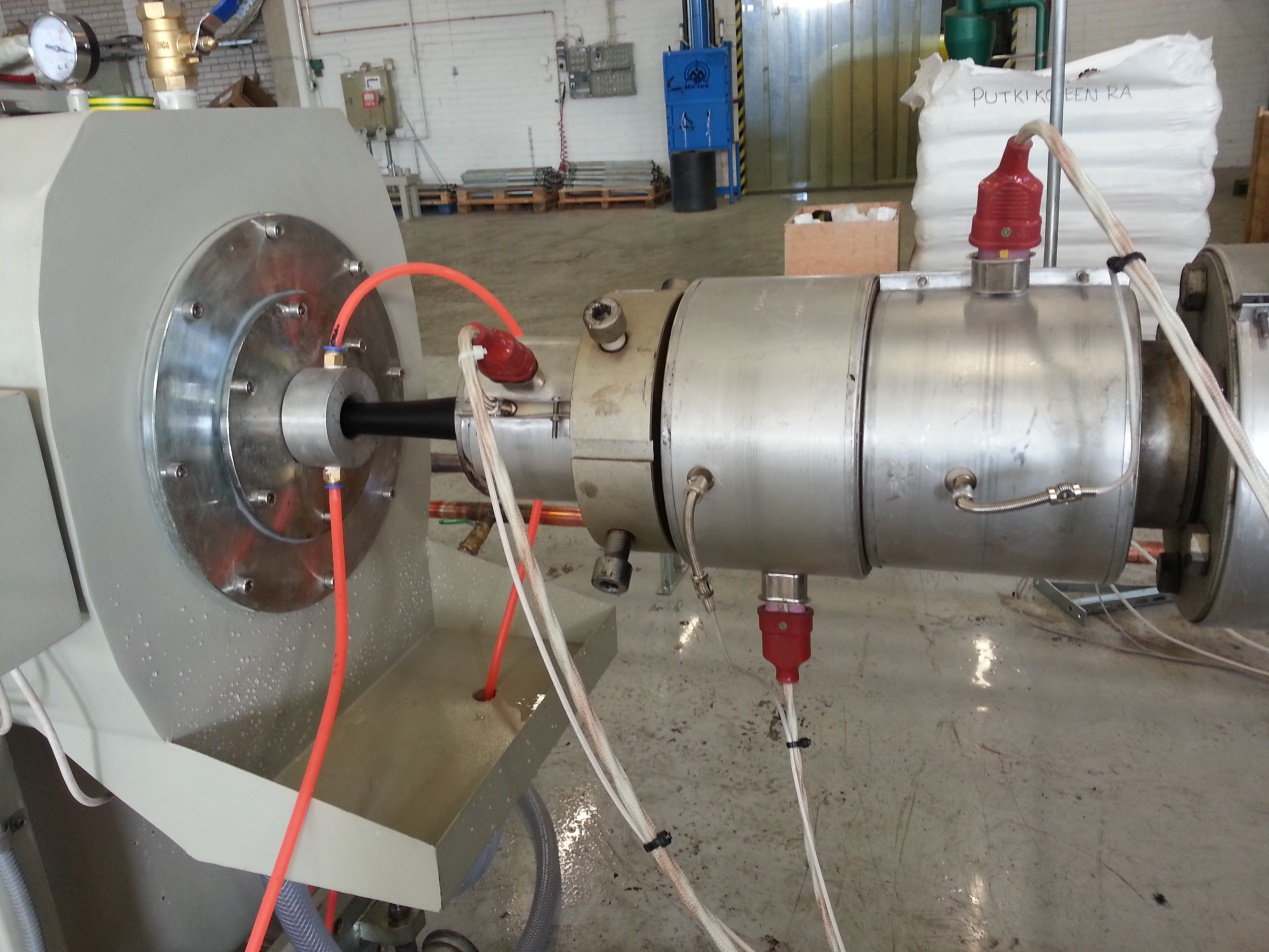

2200mm PE Large Diameter Winding Pipe machine 1.mixer and automatic feeder (capacity 1ton ) 2.Single Screw Extruder:SJ100x30 3.Single Screw Extruder: SJ65x30 4.Extruding Die and moulds 5.Vacuum Calibrating tank

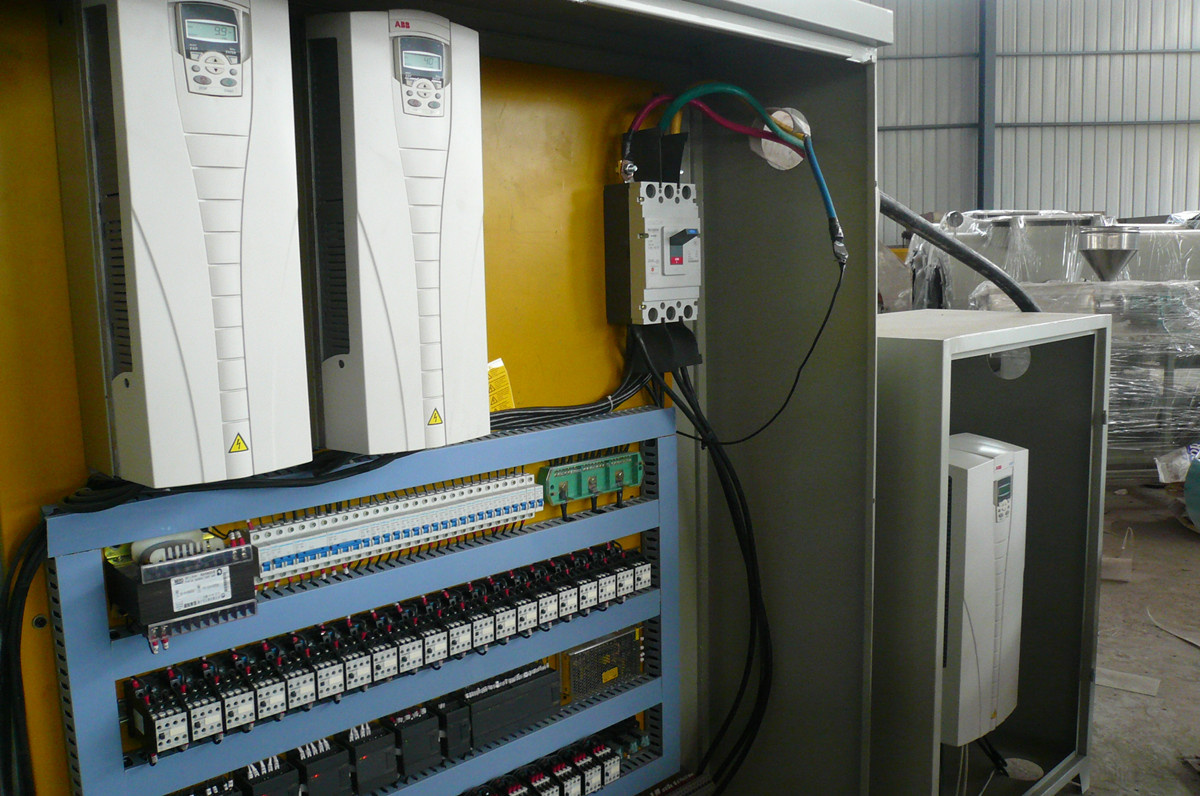

10.Rotating power roller&Stack unit 11.Siemens PLC controller 12.Including Engineer test round-trip flight

|

1set |

|

Optional |

Computer printer |

1set |

|

XGH-20pipe Ring stiffness tester (china ) SWP 630 crusher output:700kg/h |

1set 1set |

|

|

Total use Two 40HP containers |

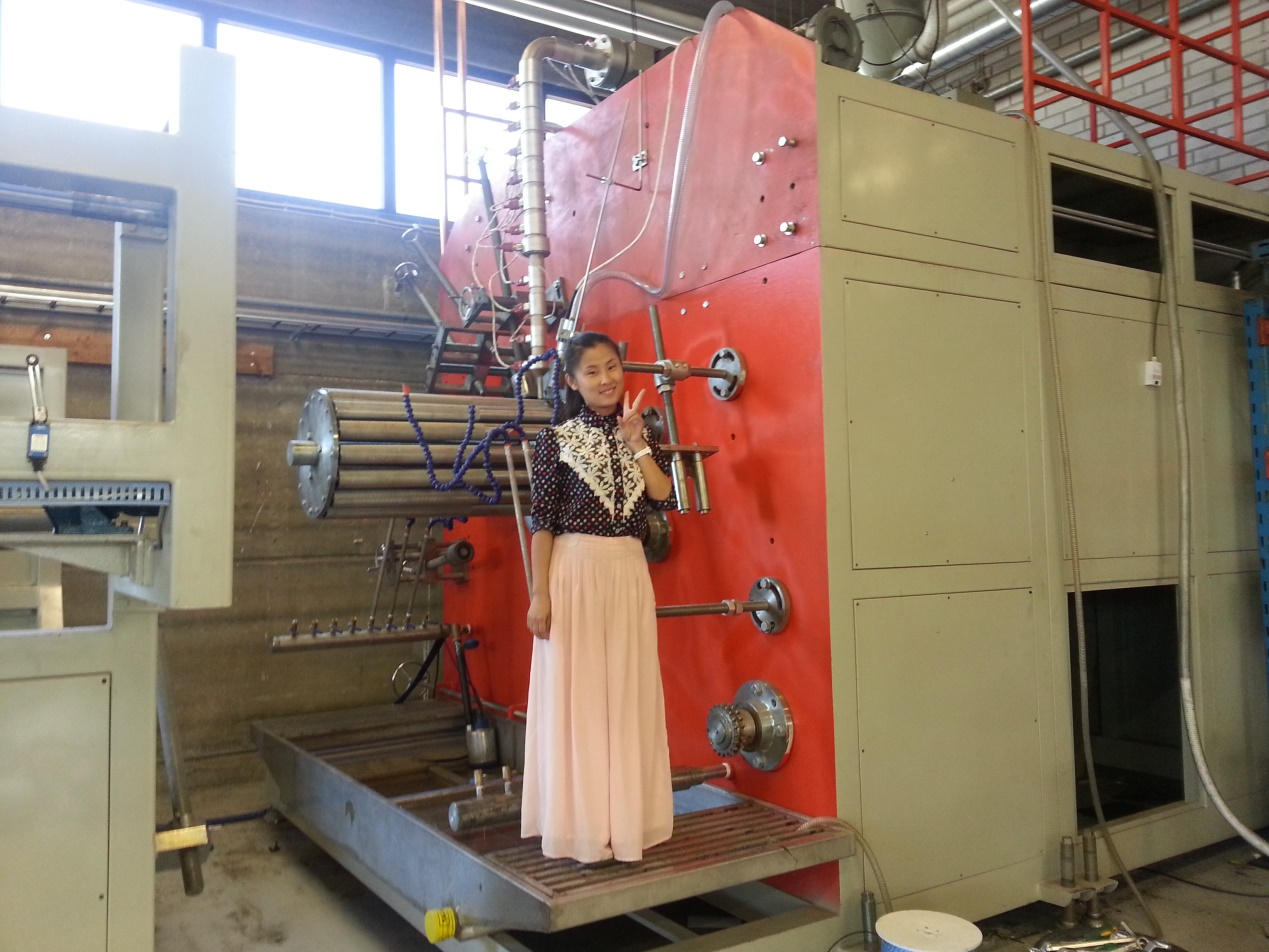

Our shipment photo

Delivery and after sales service

The package usually with PE film and wooden case or customized according to customer needs.The guarantee period is one year, start from the success of line testing in the buyer’s company. During this period, the seller will maintain the line for the buyer and change damaged accessories (excluding artificially destroy) for free. Free spare parts for important accessories are provided along with the shipment of the line. The installation, line test and worker training by the seller’s experts,usually 1-2 engineers will be sent to the buyer’s company. The experts will be available in 24 hours and the problems will be solved as soon as possible.We will also provide 24-hour network help service.