High speed PE small pipe production line

Product Application

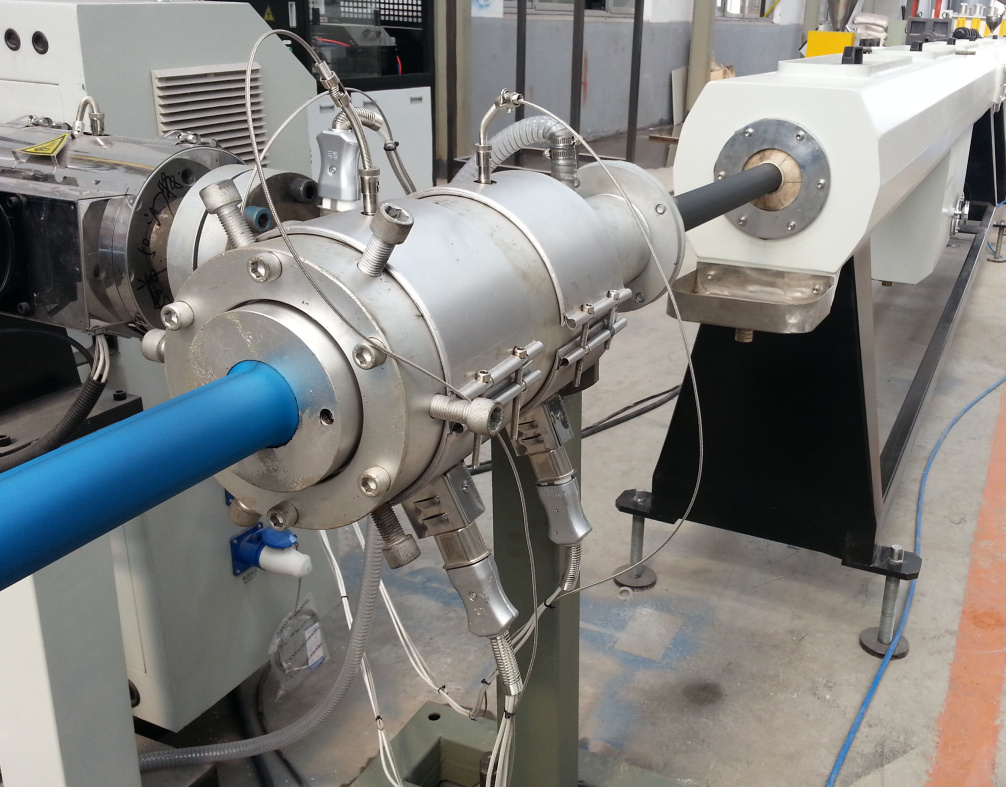

1.The pipes are extruded by the first extruder and then enter the twist form machine, at the same time the basket co-extrusion mould forms pipes' shape.

2.The pipes are based on high density PE as main raw material.

Main advantage

1.This kind of pipes have many advantages, such as corrosion resistant light, easy to fix, long time to use etc.

2.The pipes are widely used in high-way, municipal constructional, flats and so on.

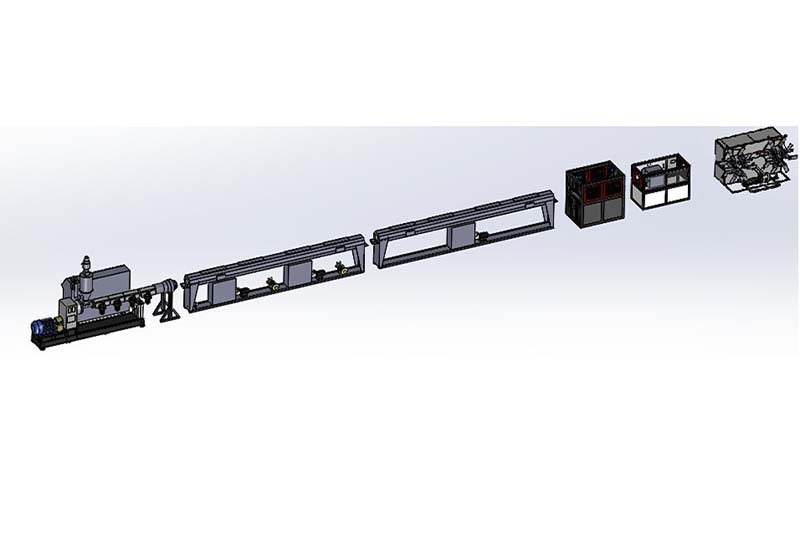

Process line

Raw material+master batches→mixing → vacuum feeding → material dryness → single screw extruder → basket co-extrusion mould → calibrator → spray vacuum calibration tank → spray cooling water tank → belt haul-off → single screw glue extruder → winder → winding roller forming → water cooler → pipe rack → finished product inspecting&packing

Packing&shipping

Packing :wooden base /pallet/film/wooden box

Shipping :

1. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

2. Customers specifying freight forwarders or negotiable shipping methods!

3. Delivery Time: 40 days after getting deposit from customer.

We design high speed mould .speed up 25m/min

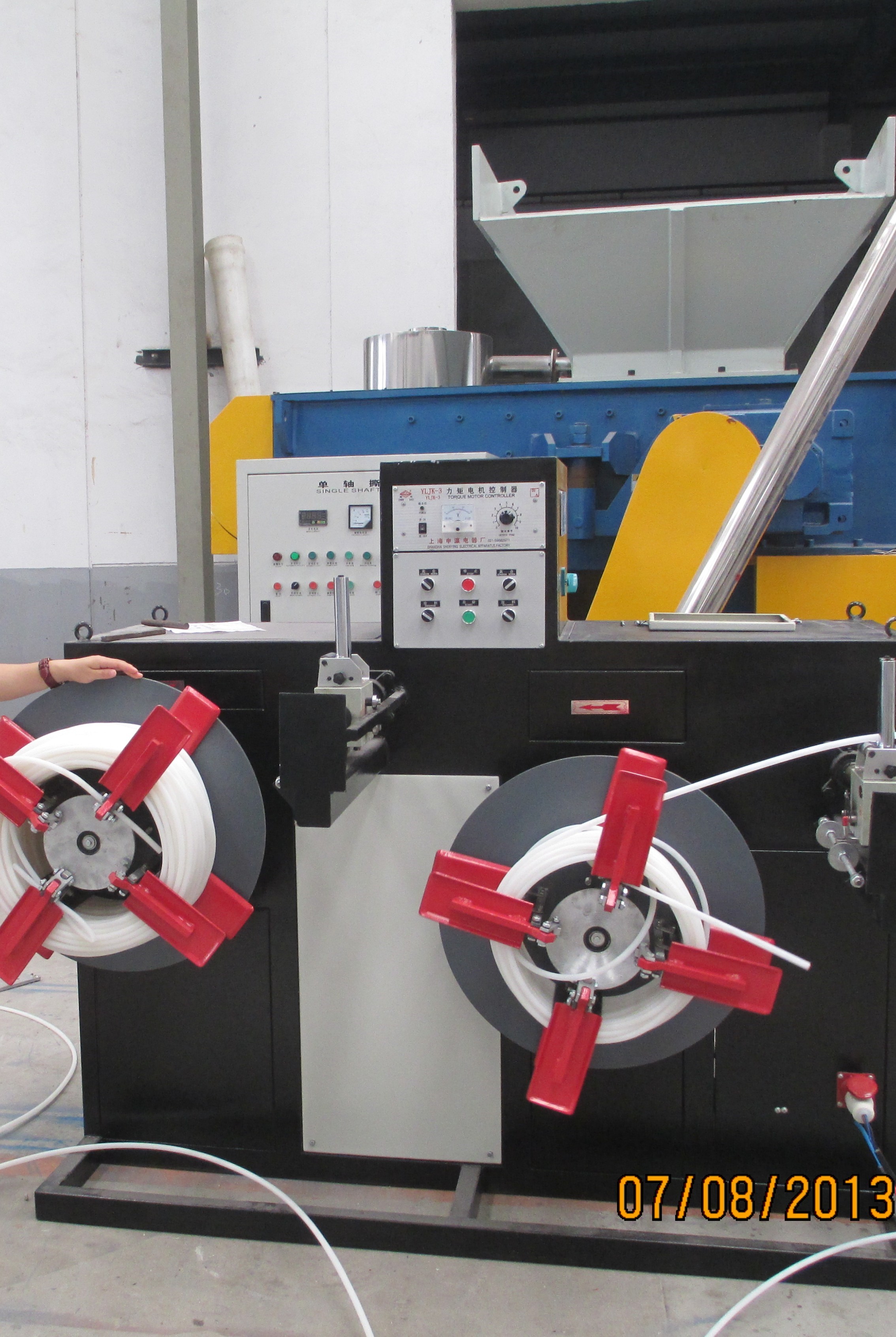

Usually diameter is 16.20.20mm we use double positon winder/coiler