| Screw :◊ Diameter of screw: Ф90mm◊ L/D: 33/1, speed of screw rotation : <=120rpm

◊ Material of screw: 38CrMoAl

◊ Surface treatment: Nitriding processing, thickness: 0.6 ~ 0.8mm, Polishing

◊ Max. rotating speed: 120rpm

Barrel:

◊ Material of Barrel: 38CrMoAlA

◊ inner processing: nitrided with thickness: 0.6 ~ 0.8mm

◊ Heating zones: 5 set

◊ Heating mode: Cast aluminum + stainless steel covering

◊ Heating power: 8KW×5set

◊ Cooling power: 0.37KW×5set

◊ Method of cooling: air blow

Driving motor:

◊ Motor power: DC 160Kw

Main electric part:

◊ Speed controller: Euro-therm, England brand

◊ Contactor: Siemens or Schneider

◊ Air-break switch: Siemens or Schneider

◊ Low-voltage circuit breaker: Schneider

Self protective system:

◊ Over current protective of motor

◊ Over pressure protective of screw. |

| Material:◊ Made by 40Cr.◊ Inner surface polished

◊ Pressure class: according to the followings

◊ Total Heating power: 42kw

Diameter spec/ wall thickness:

110mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26

125mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26

140mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26

160mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26

180mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26

200mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26

225mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26

250mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26

280mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26

315mm-----SDR 9, SDR 11, SDR 13,6, SDR 17, SDR 21, SDR 26 |

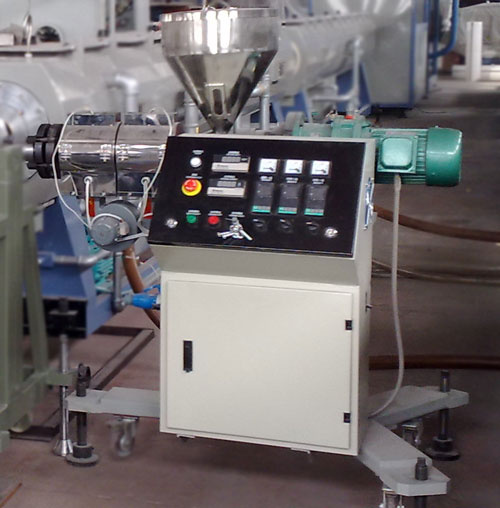

| Screw:◊ Diameter of screw: 25mm◊ L/D: 25:1

◊ Material of screw: 38CrMoAlA.

◊ Max. rotating speed:20rpm

◊ Surface treatment: Nitriding processing, thickness: 0.6 ~ 0,8mm, Polishing

Barrel:

◊ Material of Barrel: 38CrMoAlA

◊ Inner processing: nitrided with thickness: 0.6 ~ 0.8mm

◊ Heating zones: 2

◊ Heating mode: Cast aluminum and stainless steel covering

◊ Heating power: 1.2KW×2set

◊ Cooling power: 0.06KW×2set

◊ Method of cooling: air blow

Driving motor:

◊ motor power: AC 1.5 KW

Main electric part supplier :

◊ Inverter: ABB

◊ Contactor: Schneider

◊ Air Switch: Schneider

◊ indicator lamp and button: Schneider

◊ Relay: Omron

◊ Temperature controller: RKC or Omron |