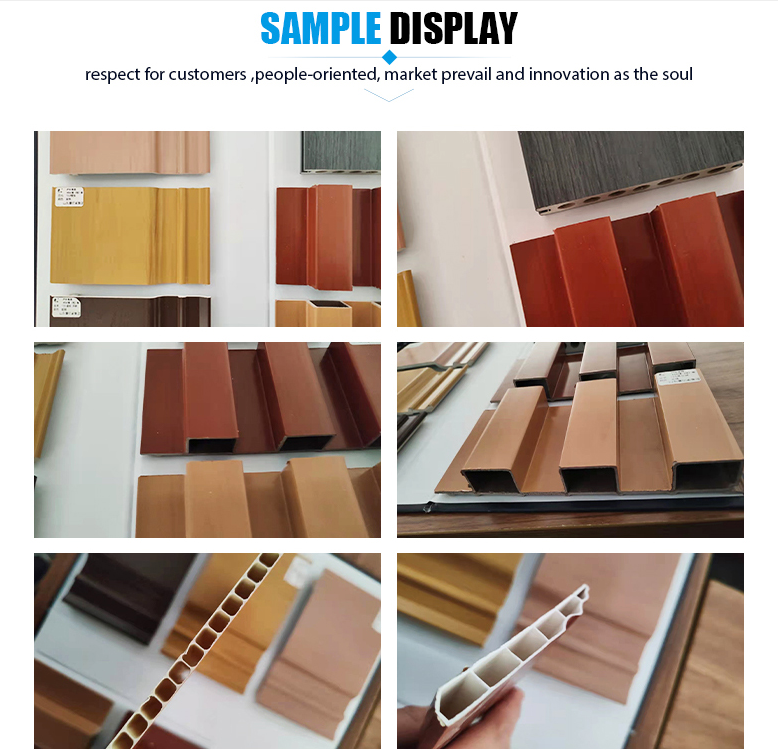

PVC Wall Board Extruder Making Machine

Products Description

The PVC Wall Board Extruder Making Machine is composed of tapered twin-screw profile extrusion equipment, equipped with corresponding molds and auxiliary equipment (such as vacuum setting cooling devices, tractors, cutting machines, etc.), which can be used for the extrusion and processing of various specifications and shapes of hard PVC wall decorative panels, ceiling gusset panels and other special-shaped profiles.

|

item |

value |

|

Screw design |

double screw extruder |

|

Screw diameter |

80/156mm |

|

Max. width of board |

600 |

|

Drawing height |

140 |

|

Drawing force |

40 |

|

Drawing speed |

0.5-5 |

|

Auxiliary equipment sum power |

31.6 |

|

Compression air |

0.6 |

|

Dimensions |

23*3*2.8m |

|

Weight |

12500kg |

|

Output |

350-400kgs/h |

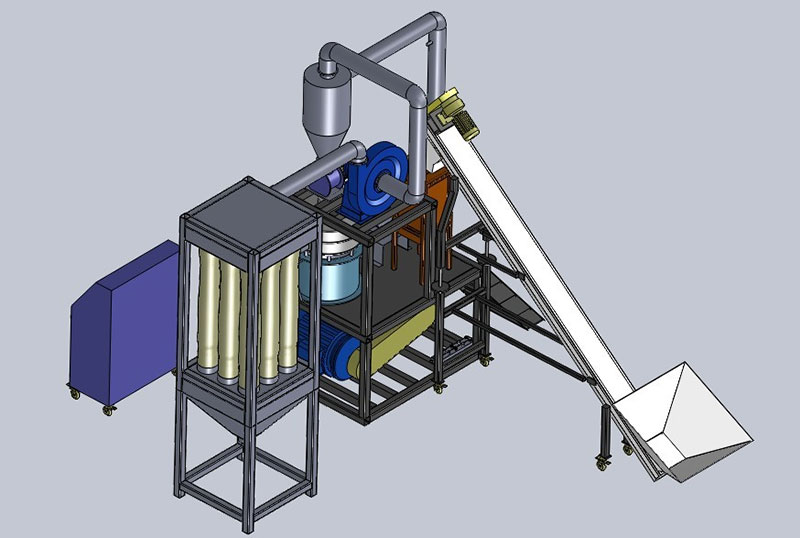

Conical twin screw extruder

• World famous brand electrical component such as Siemens,Schneider, ABB etc; • High torque gearbox with adopts NSK/SKF bearing; • Siemens/WEG original motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface.

Die head

• 3Cr13/3Cr17 material; •Complete set include extrusion die head, calibrator and cooling tank; • Apply to soft PVC, rigid PVC, soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

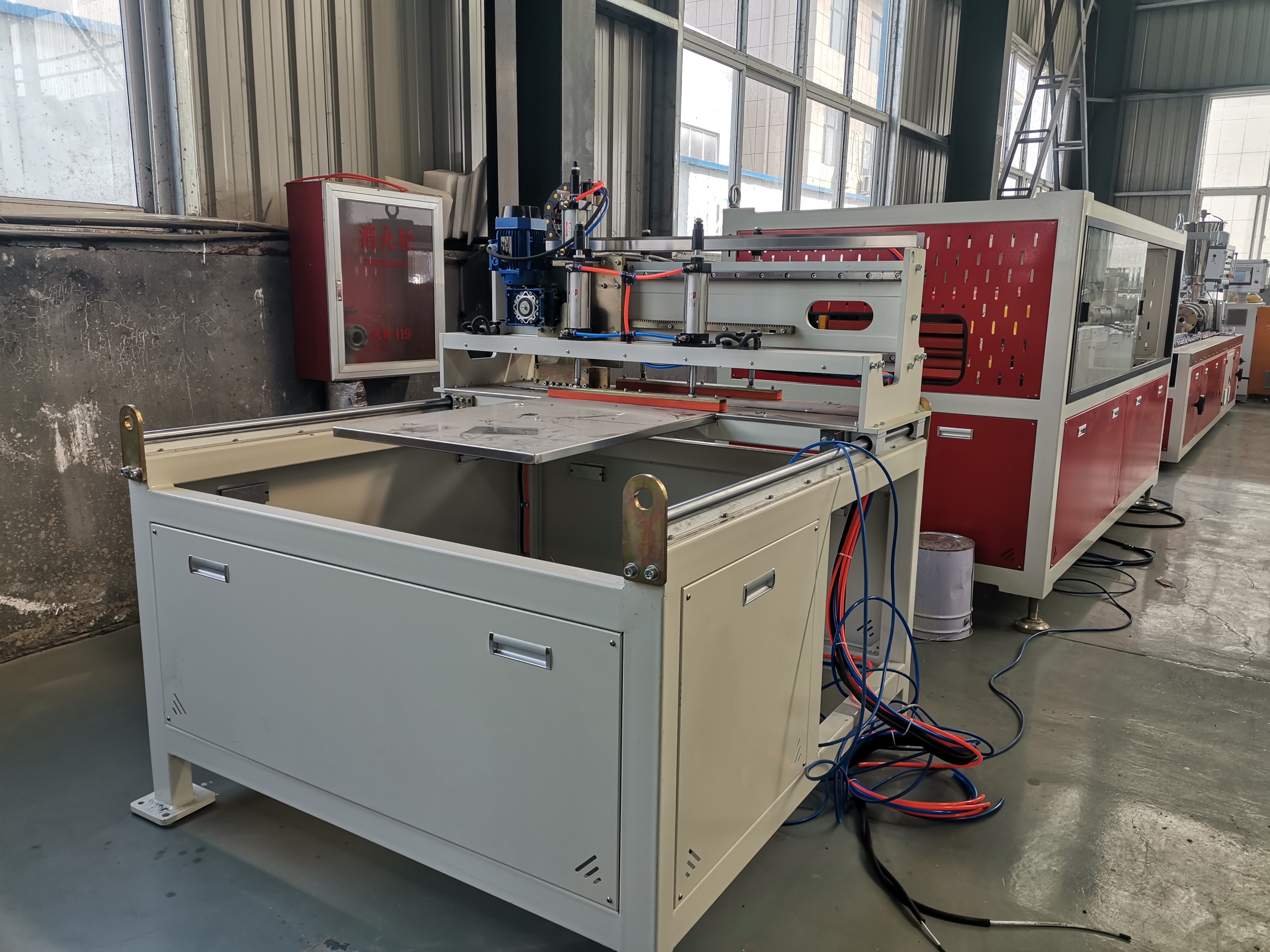

Calibration table

• Include full set of vacuum and water pump; • Length from 4m-8m; • Independent operation panel for easy operation.

Haul off&Cutter

• Upper and lower caterpillar is driven separately and speed control by frequency inverter; • Fast change type pads for easy operation; • Install plate is adopts aluminum material; • Compacting driving by pneumatic;

• Tracking cutter or lifting saw cutter with adopts double station dust collection system; • Synchronous driving by air cylinder or servo motor control.

Stacker

• Stainless steel304 as touching material; • Discharge driving by air cylinder.

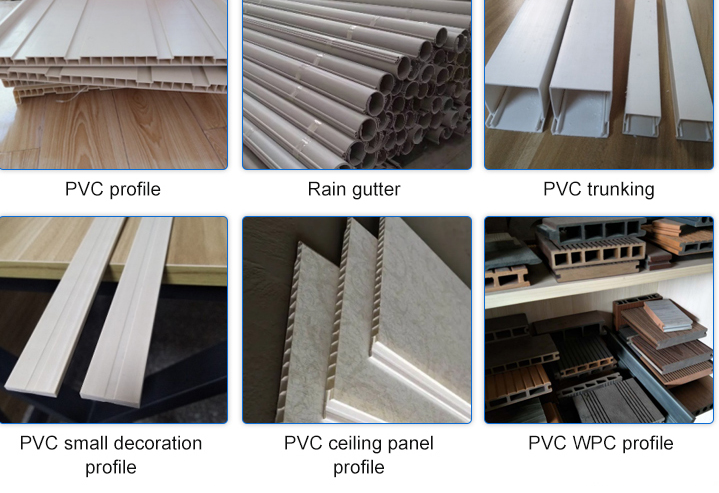

Application:

1.Household ornament: Wall and ceiling of indent independent house bathroom or kitchen;

2.Public and management place: Toilet of building and hall;

3.Common office: Ceiling of business place;

4.More indoor decoration: Hotel, business office, hospital, school, cooking room, washing room and etc.