110―250mm PVC pipe production line

Detail Technical Parameters of Each Above machines

1. ZJF-450 autoloader

| Item | Description | Unit | remarks |

|

1 |

Rated Charge Capacity | Kg/h | 450 |

|

2 |

Max charge capacity | Kg/h | 450 |

|

3 |

Motor Power | KW | 1.5 |

|

4 |

Hopper volume | Kg | 120 |

|

5 |

Spring diameter | mm | 36 |

|

6 |

Storage volume | kg | 150 |

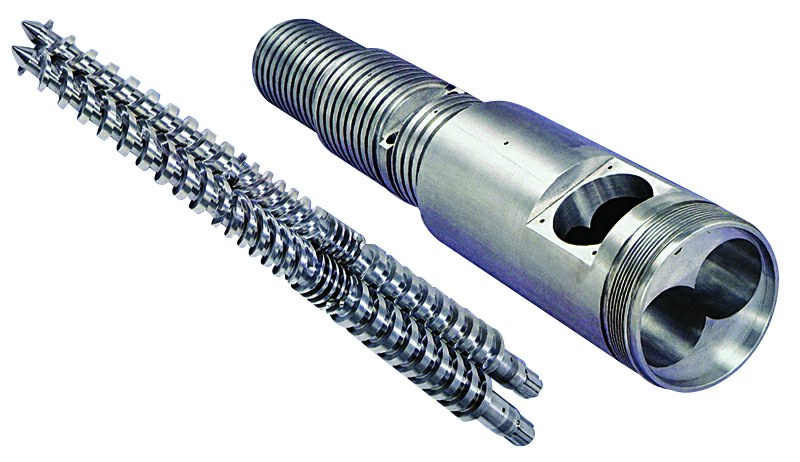

2. SJSZ80/156 Conical Double Screw Extruder

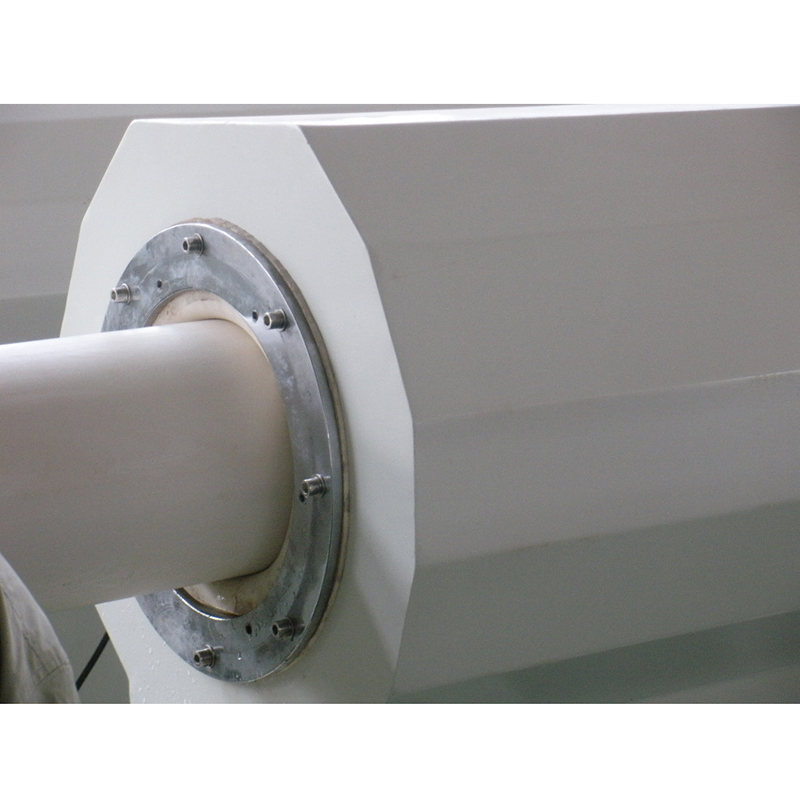

3.Moulds for 110-250mm PVC pipe

4.Vacuum Calibration and cooling Tank

| Item | Description | ZK-250 | |

| Function:

calibrate the outer diameter and cool |

|||

| 1 | Length | 6000mm | |

| 2 | Material of tank | stainless steel | |

| 3 | Cooling Type | Water Spray-pouring cooling | |

| 4 | Water Pump power | 4KW×2pcs | |

| 5 | Vacuum Pump power | 3KW×2pcs | |

| 6 | Left and right position adjustment | Manual adjusting | |

| 7 | back and forth movement | Moved by motor (cycloidal-pin wheel type) | |

5.Three claw Pedrials Hauling off Machine

| Item | Description | QY-250 |

| Function: Draw PVC pipe forward stably, the speed is synchronized with extruder speed. | ||

| 1 | The quantity of Pedrail | 3 |

| 2 | Pedrail width | 55mm |

| 3 | Pedrail available Length | 1500mm |

| 4 | Max. Hauling Force | 20KN |

| 5 | Pedrail Clamping and releasing Mode | Pneumatically Drive |

| 6 | Hauling Motor Power | 4KW |

| 7 | Hauling Speed | 0.5~5m/min |

| 8 | Driven and transmission | Central drive; cardan transmission |

| 9 | Speed Adjusting Mode | Variable frequency conversion |

| 10 | Axis Height | 1000mm |

6. Planet Cutting Machine

| Item | Description | CH-250 | |

| Function:

Meter counting automatic cutting PVC pipe in fixed length. |

|||

| 1 | Cutting mode | Automatic meter counting cutting | |

| 2 | Cutting motor power | 2.2kw | |

| 3 | Revolution motor Power | 1.5KW | |

| 4 | Blade cutting feed | Hydraulic feeding | |

| 5 | Dust collection | By air blower with 1.5kw | |

| 6 | Clamping and releasing Mode | Pneumatically | |

| 7 | Longitudinal return moving | By air cylinder pneumatically | |

| 8 | Saw material | Good quality Alloy steel | |

| 9 | Control ways | Siemens PLC control | |

| 10 | Inverter brand | Schneider brand | |

7. Stacker

| 1 | Model | SFL-250 |

| Application: Pile PVC pipes. | ||

| 2 | Material of guidance board | Stainless steel |

| 3 | Length | 6M |

| 4 | Discharging Method | Pneumatic discharge |

| 5 | Center Height | 1000mm |

| 6 | Height Adjusting | ±50mm |

| 7 | Weight | 480KG |

No 3. SRL-Z800/2500 hot and cooling mixer units

No 1. SRL-Z800/2500 mixer:

1. Application:

Mix raw material

2. Output: ≤1200kg/h

3. Equipment components:

① hot mixer

② cooling mixer

③ auto-loader

4. Features:

Mechanical parts:

Pot body adopt SUS304 stainless steel which has very good smooth and rigid surface with features of wearable, corrsion resisting,heat resisting, no-stick with raw material

Hot mixer cover material adopt ZL102 casting aluminum with polished surface

Hot and cooling mixer open adopt cylinder pneumatic drive; the main shaft of hot and cold mixer adopt NSK brand which has features of reliable stable working performance.

Hot and cooling sealing adopt silicon rubber sealing with reliable sealing effect and not deformation even at high temperature.

Electric control box parts:

Adopt intelligent RKC thermo control; Adopt famous brand motor

5. Parameter